Quartz Tanks Powering Precision Manufacturing: 8 Industry Use Cases Explained

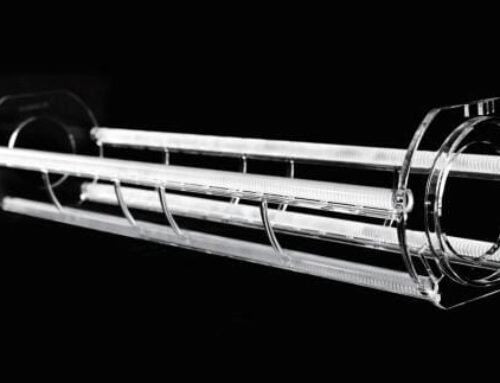

In an era where precision, purity, and temperature stability are critical to industrial performance, Quartz Tanks are emerging as a strategic asset across multiple high-value industries. From semiconductors to solar cells, chemical processing to scientific research, these ultra-pure containers offer unmatched durability and performance.

At FGQuartz, we specialize in engineering and manufacturing high-purity quartz tank solutions. Our products are designed to withstand extreme chemical, thermal, and purity requirements—helping customers across the globe elevate yield, reduce contamination, and future-proof their manufacturing lines.

What Are Quartz Tanks and Why Are They in High Demand?

Quartz Tanks are high-temperature, corrosion-resistant vessels made from fused quartz. Thanks to their unique material properties, they are widely adopted in processes that require:

High thermal endurance (operating temperatures >1100°C)

Excellent acid/base resistance

Zero metal ion contamination

Outstanding optical visibility

Long service life and low maintenance

These features make Quartz Tanks ideal for ultra-pure wet processing, chemical treatment, and thermal reactions in highly sensitive environments.

8 Real-World Applications of Quartz Tanks

1. Semiconductor Manufacturing

Used in acid etching, wafer cleaning, photoresist stripping, and thermal processing. Quartz Tanks prevent ion migration, ensuring high wafer yield.

2. Solar Photovoltaic Industry

Perfect for pre-cleaning silicon wafers, texture etching, and chemical doping. Their thermal and chemical resistance makes them ideal for high-throughput lines.

3. MEMS and Microelectronics

Used in critical wet processing applications such as deep etching and surface preparation for MEMS chips and microstructures.

4. Chemical and Electrochemical Plants

Serves as reaction chambers for corrosive liquids and high-purity chemical storage systems, enhancing safety and stability.

5. Scientific Laboratories & R&D

Applied in small-scale high-temperature reactions, acid-base mixing, and other delicate research operations.

6. Display and LED Panel Manufacturing

Helps maintain ultra-clean environments for glass substrates and panel components during chemical cleaning stages.

7. High-Purity Liquid Storage

Ensures safe and contamination-free storage of ultrapure liquids and reagents over extended periods.

8. Optical Component Treatment

Used for cleaning lenses, prisms, and specialty glass without scratching or chemical degradation.

Product Features: Designed for Industry, Engineered for Performance

Our Quartz Tanks offer a full range of design capabilities:

| Feature | Description |

|---|---|

| Material | Ultra-pure fused quartz (≥99.99% SiO₂) |

| Sizes | From 50ml lab units to 200L industrial vessels |

| Structures | Open-top, closed-lid, multi-chamber, overflow designs |

| Add-ons | Inlets/outlets, sensor ports, quartz heating elements |

| Customization | Fully OEM-compatible configurations available |

Custom Fabrication Capabilities

We support customers with fully customized tank solutions including:

Precise dimensional tolerances (±0.1mm)

Integrated thermal and fluid components

High-strength welded seams with smooth polishing

Surface options such as anti-reflection or acid-etched textures

From concept to mass production, we partner with clients to align with their processing requirements, space constraints, and automation systems.

Case Studies: Proven in Global Production Lines

✔ Leading Semiconductor Fab – Taiwan

After upgrading to FGQuartz tanks in their acid bath process, wafer contamination rates dropped by 28%, and tank lifespan doubled compared to stainless-steel alternatives.

✔ European Solar Panel Manufacturer

By integrating our closed-lid quartz tank systems into their cleaning process, they reduced acid consumption by 30% while increasing throughput by 15%.

Why Choose FGQuartz?

Over 10 Years of Quartz Fabrication Expertise

High Precision CNC & Flame Fusion Equipment

Quick Prototyping & Scalable Production

On-Time Delivery with Global Logistics Support

Technical Guidance from Design to Installation

Our international clients appreciate the combination of quality, speed, and technical support we provide throughout every phase of the project.

FAQs: Quartz Tanks

🔹 How long do Quartz Tanks typically last?

Under normal use, 5+ years of continuous operation is expected, depending on chemical exposure and thermal cycling.

🔹 Are multi-port or complex designs possible?

Absolutely. We can fabricate any tank layout including multiple inlets, overflow notches, inner liners, and more.

🔹 Are Quartz Tanks fragile?

Fused quartz is highly stable and durable when used correctly. Proper handling avoids thermal shock and mechanical stress.

🔹 Can they be used with HF (hydrofluoric acid)?

No. Quartz is not resistant to hydrofluoric acid. Special designs or liners are required for HF use.

As industries evolve toward cleaner, more efficient, and higher-precision manufacturing, Quartz Tanks are at the forefront of material innovation. Whether for production, research, or fluid control, our high-purity quartz tank solutions help our clients build better, faster, and more reliable systems.

🔗 Learn More or Request a Quote

Visit: https://www.fgquartz.com

Email: fgquartz@outlook.com

Phone/WhatsApp: +86-18552255226