Our Products

Precision Quartz Solutions

Complete Product Portfolio

Our extensive product line covers all major quartz glass applications, from semiconductor manufacturing to laboratory research. Each product is manufactured to exacting standards with 99.99% SiO2 purity and precision tolerances.

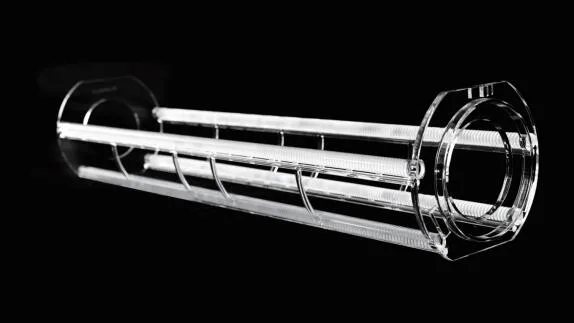

Quartz Tubes

High-precision quartz tubes manufactured using advanced fusion techniques for semiconductor diffusion furnaces, CVD reactors, optical fiber production, and high-temperature processing equipment. Available in diameters from 5mm to 500mm with wall thicknesses from 1mm to 20mm. Our tubes feature uniform wall thickness, excellent concentricity, and superior surface finish for demanding applications.

- Diameter Range: 5mm – 500mm with custom sizes available

- Wall Thickness: 1mm – 20mm, precision controlled ±0.2mm

- Purity: 99.99% SiO2, <20 ppm total impurities

- Max Temperature: 1200°C continuous, 1300°C short-term

- Applications: Semiconductor processing, CVD, diffusion furnaces, optical fiber

Quartz Rods

Solid quartz rods manufactured from premium fused silica with exceptional thermal stability and optical clarity. Precision-ground to tight tolerances with excellent straightness and surface finish. Used in optical fiber preform manufacturing, laboratory stirring rods, support structures, and custom component fabrication. Available in diameters from 3mm to 300mm with custom lengths up to 3000mm.

- Diameter Range: 3mm – 300mm, custom sizes available

- Tolerance: ±0.1mm precision grinding

- Surface Finish: Ra < 0.4μm polished surface

- Thermal Shock: Excellent resistance, 1100°C to RT

- Applications: Optical fiber, stirrers, supports, custom fabrication

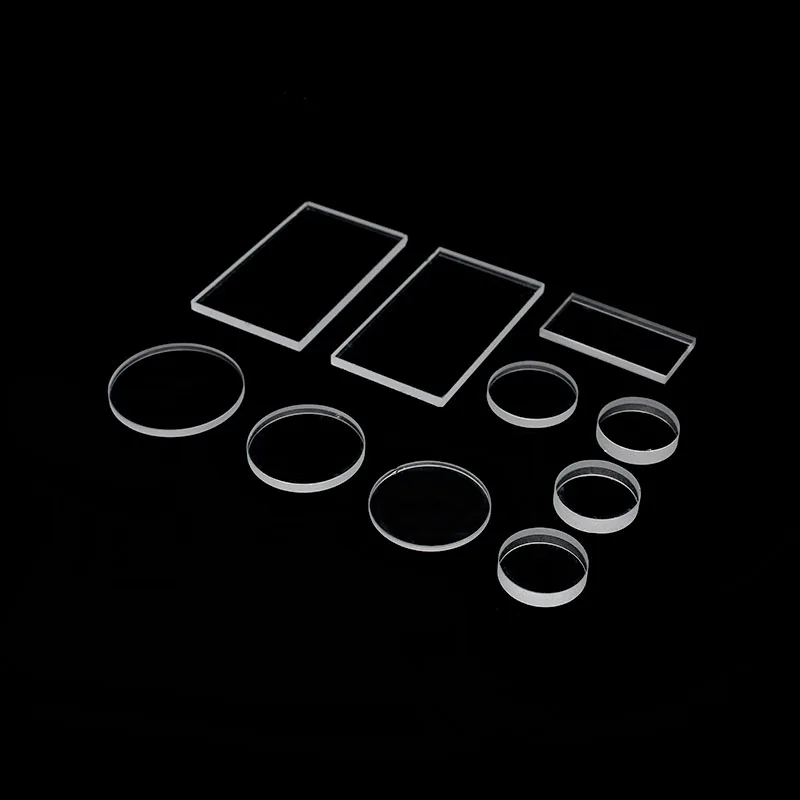

Quartz Plates

Precision-polished quartz plates with optical-grade surface finish and excellent flatness. Available in thicknesses from 0.5mm to 50mm with custom dimensions up to 1000mm × 1000mm. Our plates feature superior parallelism, minimal birefringence, and exceptional optical transmission. Perfect for optical windows, substrates, viewports, and high-temperature observation applications in research and industrial settings.

- Thickness: 0.5mm – 50mm, custom specifications

- Max Size: 1000mm × 1000mm, larger sizes on request

- Flatness: λ/4 @ 632.8nm optical grade

- Finish: Polished or ground, both sides available

- Applications: Optical windows, substrates, viewports, laser optics

Quartz Boats

Semiconductor-grade quartz boats designed for wafer processing in diffusion and oxidation furnaces. Manufactured with precise slot spacing and excellent thermal uniformity for consistent wafer processing. Available in standard and custom configurations to accommodate various wafer sizes from 2-inch to 12-inch. Our boats feature smooth surfaces to minimize particle generation and contamination.

- Wafer Sizes: 2″ to 12″ compatible, custom designs

- Slot Tolerance: ±0.2mm precision machining

- Thermal Uniformity: ±2°C across boat length

- Capacity: 25-200 wafers depending on configuration

- Applications: Diffusion, oxidation, annealing, LPCVD

Quartz Crucibles

High-purity quartz crucibles for laboratory and industrial applications requiring extreme chemical resistance and thermal stability. Available in capacities from 10ml to 50 liters with various shapes including cylindrical, conical, and flat-bottom designs. Ideal for high-temperature melting, chemical analysis, material synthesis, and crystal growth applications in research and production environments.

- Capacity: 10ml – 50L, custom volumes available

- Shapes: Cylindrical, conical, flat-bottom, custom designs

- Chemical Resistance: Excellent to most acids and alkalis

- Wall Thickness: 2mm – 10mm depending on size

- Applications: Melting, analysis, synthesis, crystal growth

Custom Components

Custom-engineered quartz solutions tailored to your exact specifications. Our experienced engineering team collaborates with clients to design and manufacture complex geometries, specialized coatings, and unique assemblies. From prototyping to production, we deliver precision-crafted components that meet your exact requirements for specialized industrial applications.

- Custom Geometries: Any shape, size, or configuration

- Engineering Support: Design assistance and optimization

- Rapid Prototyping: Fast turnaround for design validation

- Volume Production: Scalable manufacturing capabilities

Industry Applications

Specialized solutions for diverse industrial needs

Quality Assurance Standards

Every product undergoes rigorous quality control testing to ensure it meets or exceeds international standards and customer specifications.