Introduction to Quartz Glass and Its Applications

Quartz glass, often referred to as fused silica, is a high-purity material primarily composed of silicon dioxide (SiO2). Renowned for its exceptional properties, which include high thermal resistance, low expansion coefficient, and outstanding optical clarity, quartz glass serves as a crucial component in various industrial applications. Its composition contributes to its ability to withstand extreme temperatures and harsh chemical environments, making it an ideal material for industries such as electronics, optics, and construction.

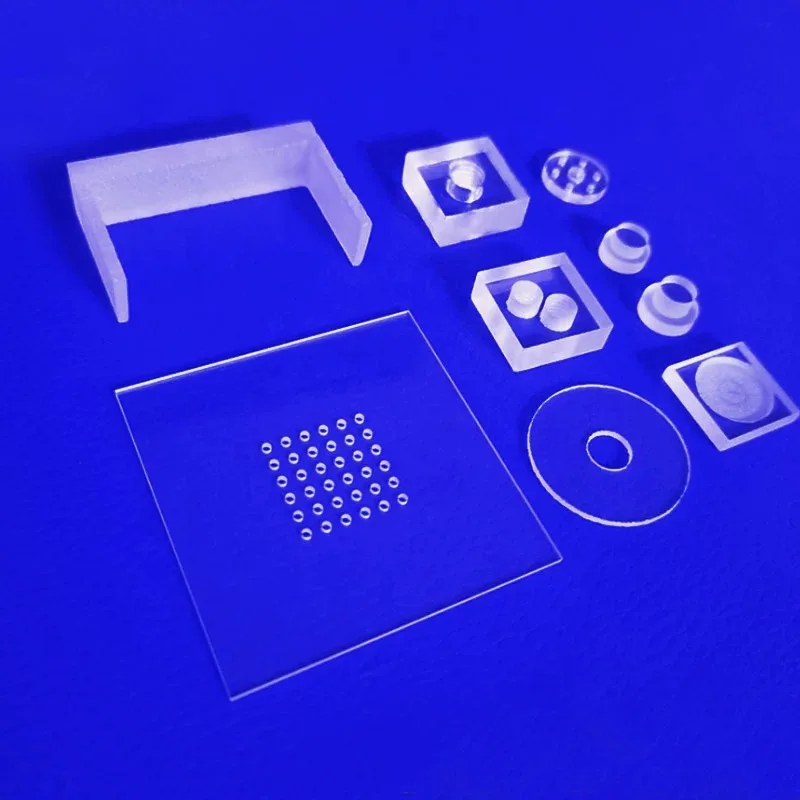

In the electronics sector, quartz glass is utilized in the manufacturing of semiconductor components and optical fibers. Its high dielectric strength and transparency to ultraviolet (UV) light allow for efficient signaling and protection against environmental factors. In optics, optical quality quartz glass is critical for producing lenses, prisms, and mirrors that require precise light manipulation and minimal surface imperfections. Its transmittance performance in the UV spectrum enhances the effectiveness of optical devices, thereby expanding their potential applications.

In the construction industry, quartz glass is often used for glazing and architectural elements due to its durability and aesthetic appeal. Surface finishing plays a fundamental role in ensuring that quartz glass components meet stringent quality standards. Proper surface finishing not only enhances the aesthetic aspect but also improves functional performance. Techniques such as flame polishing quartz, mechanical polishing quartz, and chemical polishing quartz are essential for achieving low surface roughness (Ra) and minimizing hydroxyl content, which can impact the material’s optical and mechanical properties.

Understanding the diverse applications and critical nature of quartz glass is vital as industries increasingly rely on custom quartz components finish to fulfill specific needs. The use of effective quartz glass polishing techniques ensures that end products meet both performance requirements and aesthetic expectations, underlining the importance of proper surface finishing in this versatile material.

Overview of Polishing Techniques for Quartz Glass

Quartz glass surface finishing is a critical process that significantly impacts the optical quality quartz glass. There are several prominent polishing techniques used to achieve the desired surface finish, including mechanical polishing, chemical polishing, and flame polishing quartz. Each technique has distinct processes, equipment, and outcomes, making them suitable for various applications.

Mechanical polishing quartz involves the use of abrasive materials and tools to reduce surface roughness, measured in terms of Ra (surface roughness average). This technique is often employed with polishing machines that utilize rotating pads or wheels. The mechanical process allows for a high degree of control over the final surface finish, which can reach low levels of roughness, crucial for applications that demand high UV transmission performance. However, it may introduce minor surface defects if not managed correctly, and care must be taken to avoid excessive heat that could affect the hydroxyl content quartz.

Chemical polishing quartz, on the other hand, entails using chemical solutions to etch the quartz surface, promoting a smoother finish at the molecular level. This technique is beneficial for creating custom quartz components finish since it can uniformly polish complex geometries without altering their dimensions. One significant advantage of chemical polishing is the reduction in mechanical stress, which can preserve the integrity of the quartz. However, it may not achieve the same roughness levels as its mechanical counterpart, and the process requirements demand rigorous safety and environmental controls.

In practice, many manufacturers opt to utilize a combination of both mechanical and chemical polishing. This hybrid approach allows for enhanced surface quality standards and better geometrical tolerance, making it applicable in high-tech industries such as semiconductor manufacturing and optical components. By understanding the strengths and weaknesses of each technique, industries can select the most effective method suited to their specific requirements for quartz glass polishing techniques.

Quality Standards in Quartz Glass Polishing

Quartz glass is increasingly recognized for its utility in various industrial applications, necessitating adherence to stringent quality standards in polishing processes. International standards such as ISO (International Organization for Standardization) and ASTM (American Society for Testing and Materials) provide frameworks that ensure the quality and consistency of quartz glass products. These standards play a crucial role in establishing a uniform approach to quartz glass surface finishing, contributing to enhanced optical performance and durability.

One of the primary metrics utilized to evaluate the effectiveness of quartz glass polishing techniques is surface roughness, commonly denoted as Ra. A lower Ra value indicates smoother surfaces, which is essential for applications requiring high optical quality quartz glass. Achieving optimal surface roughness not only improves light transmission but also enhances the aesthetic qualities of the finished product. Consequently, various polishing methods, including flame polishing quartz, mechanical polishing quartz, and chemical polishing quartz, are employed to meet these rigorous standards.

In addition to surface roughness, clarity is another critical factor when assessing quartz glass quality. High clarity levels are particularly important in applications involving optics or UV transmission, where any distortions can significantly impact performance. Parameters such as hydroxyl content in quartz can also influence clarity and overall optical characteristics, further emphasizing the importance of meticulous adherence to quality standards throughout the polishing process.

Durability is an integral aspect of quartz glass, impacting its performance in demanding environments. These standards ensure that the finished products can withstand mechanical stress and remain functional over extended periods. As markets continue to evolve, the importance of complying with stringent quality standards in quartz glass polishing cannot be overstated, solidifying its role in the production of custom quartz components with superior attributes.

Best Practices for Achieving High-Quality Quartz Glass Finishes

Achieving a high-quality quartz glass surface finishing requires a meticulous approach that encompasses several best practices. The selection of appropriate polishing materials is crucial; manufacturers should choose abrasives that harmonize with the specific quartz glass type and desired finish. For instance, both flame polishing quartz and mechanical polishing quartz can yield excellent results, though they cater to different project specifications. Flame polishing is often utilized for its ability to quickly eliminate surface roughness, while mechanical polishing provides a more controlled finish, making it ideal for intricate designs.

Maintaining polishing equipment is equally essential for ensuring consistent quartz glass quality standards. Regular inspection and servicing of polishing tools and machines can prevent potential issues that may arise due to wear and tear. It is advisable to keep abrasive materials clean and free from contamination to enhance the effectiveness of quartz glass polishing techniques. Notably, monitoring surface roughness parameters, such as Ra values, is key to achieving the desired finish. Capacity to uphold stringent quality control measures can significantly minimize defects that impact both aesthetics and functionality.

Emerging trends in the quartz glass finishing industry indicate a growing focus on chemical polishing quartz as a viable alternative to traditional methods. This approach not only improves surface quality but also caters to complex component shapes that mechanical means may struggle with. Innovations like enhanced hydroxyl content quartz formulations can also influence polishing outcomes by optimizing UV transmission performance. Additionally, customization of quartz components finish to meet specific client needs has gained traction, signaling a shift towards tailored polishing solutions. As the industry evolves, adopting these best practices can ensure artisans and manufacturers achieve superior quartz glass finishes that adhere to the highest standards.