Understanding UV Sterilization Systems

Ultraviolet (UV) sterilization systems are a critical component in modern water treatment equipment, air purification, and surface disinfection processes. These systems utilize UV light to neutralize pathogens and microorganisms, making them invaluable in various industries, including healthcare, food and beverage, and waste management. The underlying principle of UV sterilization centers on the ability of UV light to disrupt the DNA of microorganisms, rendering them incapable of reproduction and infection.

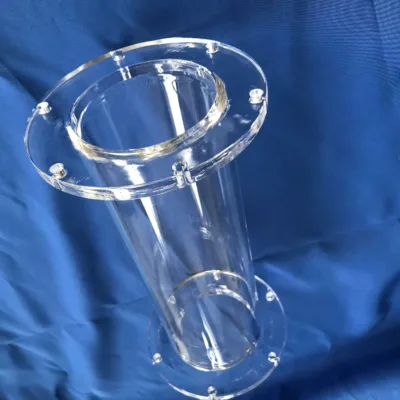

The core of a UV sterilizer consists of UV lamps housed within a quartz sleeve. The quartz sleeve protects the lamp while allowing UV light to pass through uninterrupted. This design is essential because it ensures maximum exposure of the water or air to UV light, enhancing the sterilization process. The effectiveness of these systems is largely dependent on the intensity of the UV light emitted by the lamps, the flow rate of the water or air, and the residence time, which refers to how long the water or air is exposed to the UV light.

UV sterilization presents several advantages over traditional disinfection methods. It does not rely on chemicals, which can leave harmful residues or byproducts, making it an eco-friendly option. Furthermore, it operates at a relatively low cost since UV lamps have a significant operational lifespan and require minimal maintenance. The versatility of UV disinfection allows it to be employed not just in water treatment but also in air treatment applications, such as HVAC systems, and even in the disinfection of surfaces in hospitals. By eliminating harmful pathogens effectively, UV systems contribute significantly to maintaining sanitation and safety in various environments.

In conclusion, understanding the mechanics and benefits of UV sterilization systems is crucial for anyone involved in industries where hygiene and safety are paramount. Investing in quality UV treatment equipment, coupled with proper selection of quartz sleeves and lamps, can greatly enhance the performance of disinfection systems.

The Role of Quartz Sleeves in UV Systems

In the realm of UV sterilization systems, quartz sleeves serve a pivotal function that significantly impacts overall performance. Renowned for their exceptional transparency to UV light, quartz sleeves allow the effective transmission of ultraviolet wavelengths necessary for disinfection. This property is crucial as it maximizes the efficiency of the UV sterilizer, ensuring that pathogens in water treatment equipment are effectively neutralized.

Moreover, quartz exhibits remarkable thermal resistance, enabling it to withstand high temperatures without compromising structural integrity. This trait is particularly important in applications where UV sterilizers may encounter varying thermal conditions, ensuring sustained operation and longevity of the quartz sleeve. Additionally, the chemical inertness of quartz means that it does not react with the sterilized substances, further preserving the quality and purity of treated water.

When selecting a quartz sleeve for a UV system, several factors should be taken into account. One of the primary considerations is UV transmission efficiency, which directly affects the effectiveness of the disinfection process. A sleeve with higher transmission efficiency will allow more UV light to penetrate, leading to better microbial reduction rates. Durability is another critical aspect; the lifespan of the quartz sleeve influences both maintenance intervals and overall system costs, making it essential to choose sleeves that can endure the demands of regular use without frequent replacement.

Today, various types of quartz sleeves are available in the market, each tailored for specific applications. For instance, some are designed for high-flow systems, while others may be intended for smaller, more compact UV sterilizers. By understanding the unique properties and intended uses of different quartz sleeves, users can make informed decisions that enhance the efficiency of their systems, ultimately optimizing the effectiveness of their UV disinfection processes.

Performance Optimization Techniques

Optimizing the performance of UV sterilization systems is crucial for achieving effective water treatment. A well-maintained UV sterilizer significantly enhances its efficacy in disinfecting water. One of the primary components that require attention is the quartz sleeve, which protects the UV lamp while allowing maximum UV light transmission. Regular cleaning of the quartz sleeve is necessary to prevent the buildup of minerals and other deposits that can diminish lamp output. A clean sleeve ensures that the UV light can penetrate the water effectively, thus maximizing the system’s disinfection capabilities.

Another vital aspect of performance optimization is monitoring the output of the UV lamp. Over time, UV lamps can degrade, leading to decreased disinfection efficiency. It is essential to replace lamps following the manufacturer’s recommendations, typically after a certain number of operational hours. Implementing a regular maintenance schedule that includes lamp checks will help identify any changes in performance before they adversely affect the water treatment process.

Assessing water quality and flow rates are additional steps that can significantly improve the efficiency of UV disinfection systems. High turbidity levels can shield microorganisms from UV light, so pre-treatment methods such as filtration may be required. Moreover, maintaining optimal flow rates is critical; water should ideally pass through the UV sterilizer at a speed that ensures sufficient exposure time for effective disinfection.

Common pitfalls include failing to account for changes in water conditions, which can necessitate adjustments in the system. It is also advisable to routinely evaluate and troubleshoot any performance issues that arise, ensuring that users can sustain optimal operation. By following these performance optimization techniques, including maintaining quartz sleeves, monitoring lamp output, and assessing water characteristics, users will be better equipped to ensure the highest levels of water quality and safety.

Case Studies and Best Practices

UV sterilization systems have gained prominence across various sectors due to their effectiveness in disinfection and purification. In healthcare settings, a notable case involves a hospital that implemented a UV disinfection system in its surgical wards. By utilizing high-quality quartz sleeves, the facility was able to improve the efficiency of their UV sterilizer significantly. The choice of the right quartz sleeve allowed for optimal light transmission and minimized UV absorption, resulting in higher disinfection rates and a noticeable reduction in hospital-acquired infections.

In the aquaculture industry, another impressive case showcases a fish farm employing a water treatment equipment system integrated with a UV sterilizer. The farm switched to quartz sleeves designed for high flow rates and robust resistance to biofouling. This transition not only reduced maintenance downtime but also ensured that the aquatic environment remained pristine, leading to healthier fish stocks and improved yield. The success of this operation was further bolstered by regularly monitoring the quartz sleeve’s condition, allowing for timely replacements that kept the system operating at peak efficiency.

The food processing sector also benefits from effective UV sterilization practices. A leading food processing company adopted a UV disinfection system to sanitize their processing water. By carefully selecting quartz sleeves that matched the specific requirements of their UV sterilizer, they were able to enhance the system’s performance while ensuring compliance with safety regulations. Regular assessments of the quartz sleeves revealed optimal conditions for functioning, and routine cleaning protocols significantly extended their lifespan. This practice not only maximized efficiency but also resulted in cost savings related to equipment maintenance.

Overall, these case studies illustrate the importance of selecting the appropriate quartz sleeve and maintaining UV sterilization systems effectively. Best practices derived from these real-world applications can serve as valuable guidelines for organizations aiming to enhance their water treatment operations and improve disinfection outcomes.