Quartz glass is a high-performance material celebrated for its exceptional thermal resistance, optical transparency, chemical inertness, and electrical insulation. These properties make it indispensable in high-precision industries, but they also introduce unique challenges in fabrication—particularly when tight tolerances and complex geometries are required. This is where CNC machining quartz glass becomes a decisive manufacturing solution.

By leveraging computer numerical control (CNC) technology, manufacturers can achieve high dimensional accuracy, repeatability, and controlled material removal when processing quartz glass. In this guide, we explore the fundamentals of CNC machining quartz glass, its advantages, the machining workflow, critical technical considerations, applications, and how to select a qualified service provider.

What Is CNC Machining Quartz Glass?

CNC machining quartz glass refers to the computer-controlled cutting, drilling, milling, or grinding of quartz glass components using programmed toolpaths. Unlike manual machining, CNC systems execute consistent and repeatable movements based on CAD/CAM data, reducing operator-induced variability—an essential advantage when working with brittle materials such as quartz glass.

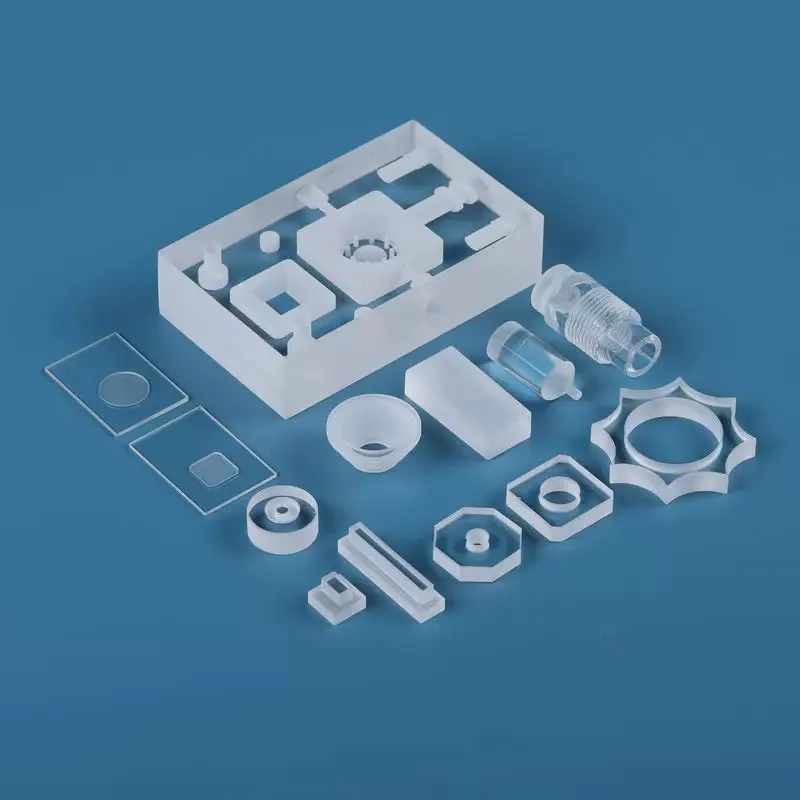

CNC machining enables the transformation of digital design files (e.g., CAD models) into precision quartz glass components with controlled tolerances and surface quality. This approach allows for the fabrication of features such as precision bores, slots, steps, contours, and complex 3D geometries that would be difficult or impractical to achieve using manual methods.

Key Advantages of CNC Machining Quartz Glass

High Precision and Dimensional Control

CNC machining of quartz glass typically achieves dimensional tolerances in the range of ±0.02 mm to ±0.1 mm, depending on part size, geometry, and finishing requirements. This level of precision is well suited for semiconductor, optical, and laboratory applications where dimensional consistency directly affects performance.

Excellent Consistency and Repeatability

Once machining parameters are validated, CNC systems reproduce identical parts across batches, ensuring consistent quality in both prototype and production runs.

Capability for Complex Geometries

CNC machining supports multi-axis operations, allowing the production of complex contours, stepped features, internal channels, and custom profiles in quartz glass components.

Reduced Material Waste and Risk

Controlled toolpaths, stable fixturing, and optimized cutting parameters minimize chipping, cracking, and scrap—particularly important given the cost and brittleness of high-purity quartz glass.

Scalability from Prototype to Production

CNC machining supports low-volume prototyping as well as repeat production, enabling design validation before scaling to larger manufacturing volumes.

CNC Machining Quartz Glass: Process Overview

1. Design and CAD Modeling

Machining begins with a detailed CAD model defining dimensions, tolerances, and functional features. Common data formats include STEP and IGES for compatibility with CAM software.

2. CAM Programming and Toolpath Generation

CAM software converts the CAD model into machining instructions. Cutting strategies, feed rates, spindle speeds, and tool selections are optimized specifically for quartz glass to reduce mechanical and thermal stress.

3. Material Preparation and Fixturing

Quartz glass blanks are inspected for surface defects and securely mounted using non-damaging fixtures. Proper fixturing is essential to prevent vibration while avoiding stress concentration.

4. CNC Machining Operations

Operations may include milling, drilling, turning, or grinding. Diamond tools are commonly used due to their hardness and wear resistance. Cutting parameters are kept conservative to reduce the risk of chipping or micro-cracking.

5. Post-Machining Finishing

Depending on application requirements, components may undergo edge rounding, polishing, or surface finishing. Optical or high-purity parts often require smoother surface finishes.

6. Inspection and Quality Verification

Finished parts are inspected for dimensional accuracy, surface quality, and overall conformity to specifications using precision measuring instruments.

Critical Technical Considerations When Machining Quartz Glass

Material Brittleness

Quartz glass is brittle and sensitive to mechanical shock. Low cutting forces, gradual material removal, and stable machining conditions are essential.

Tool Selection

Diamond-based tooling (PCD or natural diamond) provides clean cuts and longer tool life, reducing surface damage.

Thermal Control

Although quartz glass withstands high temperatures, localized heat during machining can induce stress. Controlled cooling methods help maintain material integrity.

Cleanliness and Contamination Control

For semiconductor or laboratory applications, machining environments and handling procedures must minimize particle and metallic contamination.

Design for Manufacturability

Avoiding excessively thin walls, sharp internal corners, and abrupt cross-section changes reduces machining risk and improves yield.

Applications of CNC Machined Quartz Glass Components

Semiconductor Manufacturing

- Process tubes, nozzles, chambers, and wafer handling components

- High purity and dimensional accuracy support contamination-sensitive processes

Optics and Photonics

- Optical windows, light guides, laser components, and sensor housings

- Precision geometry ensures stable optical performance

Medical and Laboratory Equipment

- Cuvettes, reaction vessels, analytical components, and micro-fluidic structures

- Chemical inertness ensures sample integrity

Aerospace and Advanced Engineering

- Sensor housings, thermal components, and optical assemblies

- Reliable performance under thermal cycling and vacuum conditions

Industrial Heating and Electronics

- Insulating components, heating element supports, and precision fixtures

- High temperature resistance and electrical insulation are critical

How to Choose a CNC Machining Quartz Glass Service Provider

Proven Quartz Glass Experience

Select a supplier with demonstrated experience machining quartz glass—not just general CNC capabilities.

Appropriate Equipment and Tooling

Advanced CNC machines and dedicated diamond tooling improve accuracy and surface quality.

Quality Control Systems

Look for structured inspection processes and documented quality assurance procedures.

Clean Processing Capability

For high-purity applications, cleanliness in machining and handling is essential.

Engineering and Design Support

Providers offering DFM guidance help optimize designs, reduce cost, and improve manufacturability.

Production Capacity and Reliability

Ensure the supplier can support both prototypes and repeat production with consistent lead times.

FAQs About CNC Machining Quartz Glass

Q: What machining tolerances are realistic for quartz glass?

A: Typical tolerances range from ±0.02 mm to ±0.1 mm, depending on part geometry, size, and finishing requirements.

Q: Is CNC machining suitable for all quartz glass types?

A: Yes. CNC machining is commonly applied to fused quartz and high-purity quartz glass, with parameters adjusted for material characteristics.

Q: Is CNC machining cost-effective?

A: CNC machining reduces scrap, improves repeatability, and lowers long-term cost for precision or repeat production, even if initial setup costs are higher.

Q: Can CNC machining produce optical-grade surfaces?

A: CNC machining establishes geometry; optical-grade surfaces typically require additional polishing processes.

Conclusion

CNC machining quartz glass is a critical manufacturing method for producing precision components that fully utilize quartz glass’s thermal, chemical, and optical advantages. Through controlled machining, complex designs can be realized with reliable dimensional accuracy and repeatability.

By understanding the machining process, technical constraints, and supplier selection criteria, manufacturers can confidently integrate CNC-machined quartz glass components into advanced systems across semiconductor, optical, laboratory, and industrial applications.