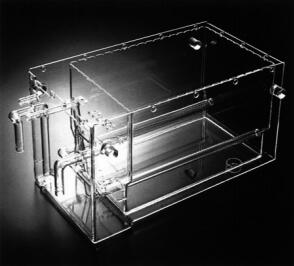

Quartz tanks play a vital role in semiconductor manufacturing, where maintaining cleanliness and preventing contamination is essential. That’s where quartz vessels come in. These high-purity vessels are essential components in semiconductor wet processing, serving roles in chemical baths, wafer cleaning, and etching operations. With excellent thermal and chemical resistance, fused silica tanks support ultra-clean environments for wafer production.

At Fgquartz, we specialize in custom fused silica tanks designed to meet the exacting standards of the semiconductor industry.

What Are Quartz Tanks?

Quartz tanks are containers made from high-purity fused silica (SiO₂ ≥ 99.99%) used for holding ultra-pure chemicals or high-temperature solutions during the semiconductor fabrication process. These tanks are chemically inert, thermally stable, and ideal for cleanroom environments.

high-purity quartz containers are typically used for:

- 🔬 RCA Cleaning

- 🧪 HF, HCl, and SC1/SC2 Wet Etching

- ♻️ Wafer Rinsing and Drying

- 🔥 High-Temperature Thermal Baths

They ensure no contamination, no particle shedding, and maximum chemical compatibility, which is critical for modern integrated circuit production.

Advantages of Quartz Tanks in Semiconductor Processes

Fgquartz quartz tanks offer a range of benefits:

- ✅ High Chemical Resistance – Withstands acids like HF, HNO₃, HCl, and bases like NH₄OH

- ✅ Thermal Stability – Operates up to 1100°C without deformation

- ✅ Ultra-High Purity – Eliminates metal ion leaching and particle generation

- ✅ Custom Shapes and Sizes – Designed for specific tools, benches, or reactors

- ✅ Smooth Surfaces – Reduce contamination and make cleaning easier

- ✅ Safe for Cleanrooms – Non-outgassing and compliant with semiconductor-grade environments

Applications of Quartz Tanks in Semiconductor Manufacturing

Fgquartz quartz tanks are widely used in:

🧼 Wet Benches & Cleaning Stations

Used for RCA cleaning, SC1/SC2, and BOE processes that prepare wafers before and after deposition or etching steps.

⚗️ Chemical Etching Baths

chemical-resistant tanks hold hydrofluoric acid (HF) and other corrosive etchants for oxide removal.

🌡 High-Temperature Baths

In oxidation or annealing processes, quartz process tanks can withstand thermal cycling without cracking or contaminating wafers.

🧊 Cooling or Rinse Tanks

Holding ultrapure water (UPW) during wafer rinsing and final drying.

Why Choose Fgquartz for Quartz Tanks?

With over 20 years of experience in quartz fabrication, Fgquartz offers:

- 🏭 OEM and Custom Fabrication

- 🧪 Precision Tolerance Control

- 🌐 Global Shipping and Export-Ready Support

- 🔩 Optional Lids, Baffles, Overflow Sections, and Ports

- 🤝 Engineering Support for system integration

Every tank is manufactured from high-purity quartz and tested to meet industry standards for mechanical, thermal, and chemical resistance.

for wafer boats, tubes, viewports, and more.

Technical Specifications

| Property | Specification |

|---|---|

| Material | Fused Quartz (SiO₂ ≥ 99.99%) |

| Temperature Range | -40°C to 1100°C |

| Chemical Compatibility | HF, HCl, HNO₃, NH₄OH, SC1/SC2 |

| Wall Thickness | 3–10 mm (customizable) |

| Dimensions | As per customer request |

| Surface Finish | Polished interior, flame-polished edges |

Get a Quote or Custom Design

Whether you need a standard wet bench tank or a fully customized reactor tank, Fgquartz can deliver the right solution for your process.

fgquartz@outlook.com

🌍 Visit our homepage to explore more about our quartz expertise.

Precision-built quartz tanks for the semiconductor industry — trusted by fabs, labs, and OEMs worldwide.