Introduction to Quartz Tanks

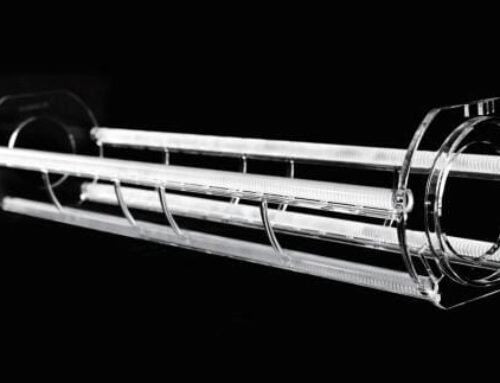

Quartz tanks have emerged as a vital component in chemical laboratories due to their exceptional chemical resistance and structural integrity. Composed primarily of silicon dioxide, these tanks are characterized by their transparent, crystalline appearance, allowing for easy observation of contained substances. The unique properties of quartz, including its durability and thermal stability, make it an ideal choice for laboratory environments where the handling of corrosive materials is commonplace.

The structure of quartz tanks is designed to withstand harsh chemical interactions that would otherwise degrade alternative materials. Unlike plastic or metal containers, quartz does not react with various acids or bases, minimizing contamination and ensuring the quality of experiments. This non-reactive nature is crucial in laboratories dealing with volatile compounds, as any reaction between the container and its contents could lead to inaccurate results and hazardous situations.

Material choice in laboratories is paramount, as it directly influences the safety, efficiency, and reliability of chemical processes. Quartz tanks facilitate a controlled environment for research and analysis by providing a stable medium free from leaching elements. The transparent nature of these tanks also allows scientists to monitor reactions visually, contributing to better data collection and analysis.

In addition to their chemical resistance, quartz tanks often exhibit excellent thermal properties, enabling them to withstand high temperatures without compromising structural integrity. This aspect is especially important in laboratories where heating and cooling processes are routine. Therefore, the combination of these attributes makes quartz tanks indispensable in achieving precise and accurate chemical experiments.

As we delve deeper into the specifics of quartz tanks and their applications in chemical labs, it becomes evident why their properties are invaluable for modern scientific endeavors. The strategic selection of quartz as a material reinforces the crucial role it plays in ensuring reliable outcomes in laboratory settings.

Properties of Acid and Corrosion Resistance

Quartz, a mineral composed of silicon dioxide (SiO2), possesses several properties that contribute to its remarkable acid and corrosion resistance, making it an ideal material for chemical laboratory environments. At the molecular level, quartz exhibits a crystalline structure characterized by a three-dimensional network of silicon-oxygen tetrahedra, which enhances its overall strength and stability. This robust configuration allows quartz to maintain its integrity even when exposed to harsh conditions, thereby minimizing the risk of degradation or damage.

One of the key attributes of quartz is its inherent durability. Quartz is known for its high resistance to temperature fluctuations, mechanical stress, and chemical reactions. It withstands exposure to a wide variety of aggressive chemicals, including strong acids and bases, without undergoing structural changes. This property is particularly advantageous in chemical labs, where the handling of reactive substances is commonplace. Unlike many other materials that may corrode or degrade under similar conditions, quartz remains unaffected, thus ensuring a reliable and long-lasting option for tank construction.

Moreover, the low porosity of quartz plays a significant role in its acid resistance. The tightly bound molecular structure means that quartz absorbs very little moisture, reducing the likelihood of chemical permeation that can lead to corrosion. This quality not only enhances the lifespan of quartz tanks but also ensures that the purity of the substances handled within is maintained. Chemical labs benefit greatly from using quartz tanks, as they can assure consistent performance and minimize the risk associated with material failures, thereby upholding safety standards and operational efficiency in laboratory processes.

Applications of Quartz Tanks in Chemical Labs

Quartz tanks play a pivotal role in the functionality and efficiency of chemical laboratories, primarily due to their exceptional acid and corrosion resistance features. These tanks are predominantly utilized for storing, mixing, and handling various chemicals, making them invaluable in ensuring safe and accurate laboratory processes. The innovative properties of quartz allow it to withstand harsh environments without deteriorating, which is critical in settings where chemical reactions might pose risks to both personnel and equipment.

One of the primary applications of quartz tanks is in the storage of highly corrosive substances. Laboratories involved in the pharmaceutical, chemical manufacturing, and semiconductor industries often require robust tanks that can safely hold acids and other reactive compounds without risking contamination or structural failure. In such applications, quartz tanks can be relied upon to preserve the integrity of the stored materials, minimizing the potential for spills or leaks.

Additionally, quartz tanks are essential in mixing processes. The chemical lab environments often require precise formulations that necessitate the mixing of different reagents. The inert nature of quartz ensures that no unwanted reactions occur, enabling scientists to achieve accurate and repeatable results. For example, in biochemistry laboratories, quartz tanks are utilized to mix biochemical solutions, ensuring that the mixtures remain pure and effective for research purposes.

Moreover, quartz tanks are used in the handling of gases and other volatile materials. Their temperature resistance and stability under pressure make them suitable for applications involving gas-phase chemicals, such as in the preparation of reactants for various experiments. Numerous industries, including food and beverage, petroleum, and environmental testing, leverage quartz tanks for these specialized functions, highlighting the versatility and essential nature of this material in modern chemical laboratories.

Advantages of Using Quartz Tanks

Quartz tanks have gained recognition in chemical laboratories for their distinct advantages over traditional materials such as glass and plastic. One of the most noteworthy benefits of quartz is its exceptional longevity. Unlike glass that can shatter or plastic that may degrade over time, quartz exhibits remarkable durability. This resilience not only extends the lifespan of the laboratory equipment but also reduces the frequency and costs of replacements.

Another significant advantage of quartz tanks is their reduced risk of contamination. In chemical processes, maintaining the purity of substances is paramount. Quartz is known for its non-reactive properties and smooth surface, which minimizes the potential for chemical leaching. This ensures that the integrity of the stored substances remains intact, thus enhancing the reliability of experiment results and analyses.

Moreover, quartz tanks boast superior thermal stability, making them highly suitable for a wide range of temperature-sensitive applications. They can withstand extreme temperatures without warping or breaking, unlike glass or plastic, which may become compromised under similar conditions. The ability to maintain consistent temperatures is crucial in various chemical reactions and processes. Therefore, using quartz tanks can lead to more accurate and reproducible outcomes in laboratory experiments.

In addition to these benefits, quartz’s transparent nature allows for easy monitoring of chemical reactions and fluid levels within the tanks, further enhancing operational efficiency. Laboratories can obtain real-time visibility, facilitating timely interventions when necessary. Overall, the advantages of quartz tanks—such as longevity, reduced contamination risks, and superior thermal stability—clearly demonstrate their value as a dependable choice for modern chemical laboratories.

Comparative Analysis with Other Materials

When selecting storage solutions in chemical laboratories, the choice of material is critical. Quartz tanks are often compared with other commonly utilized substances such as PVC, polyethylene (PE), and borosilicate glass. Each of these materials exhibits distinct characteristics that influence their suitability for various chemical applications.

Quartz tanks are renowned for their exceptional chemical resistance, particularly against a wide range of acids and corrosive agents. Their ability to withstand high temperatures further amplifies their effectiveness in lab settings that handle volatile substances. In contrast, PVC and PE offer good chemical resistance; however, they may not withstand the extreme temperatures that quartz can tolerate. For applications requiring exposure to concentrated acids or bases, quartz stands out as a superior option.

Borosilicate glass is another popular choice in laboratory environments, valued for its resistance to thermal shock and excellent chemical compatibility. While borosilicate glass can be appropriate for certain applications, it is particularly vulnerable to scratches and impacts, which can compromise its integrity over time. In situations where mechanical stress is a consideration, quartz tanks provide enhanced durability, making them less likely to fracture under pressure.

Cost-effectiveness is an important factor as well. PVC and PE are usually more affordable upfront, which might appeal to budget-conscious laboratories. However, when considering the long-term implications, the durability and performance of quartz tanks can lead to reduced maintenance and replacement costs over time. Ultimately, the choice of tank material should align with the specific needs of the laboratory, including chemical compatibility, anticipated usage conditions, and financial constraints.

Installation and Maintenance of Quartz Tanks

Installing and maintaining quartz tanks in chemical laboratories is crucial for ensuring their longevity and performance. Quartz tanks, known for their excellent acid and corrosion resistance, require careful handling during installation to avoid damage. It is advisable to set up these tanks on a stable and level surface to prevent any undue stress or imbalance that may arise from uneven weight distribution. When placing the tank, use non-abrasive materials to support the base and avoid direct contact with hard surfaces. As quartz is a brittle material, any sudden impact can cause fractures that compromise the integrity of the tank.

Proper handling techniques should be implemented when transporting quartz tanks. Always use appropriate lifting equipment or protective gear to ensure safety during transit. Be mindful of the temperature fluctuations and environmental conditions, as extreme changes can lead to thermal shock, causing cracks or breaks. During installation, ensure that all connections to pipes and other equipment are secure yet not overly tightened, as excessive torque can lead to stress fractures.

Maintenance is equally important for the optimal functioning of quartz tanks. Regular cleaning should be carried out using pH-neutral detergents and non-abrasive scrubbing tools to prevent scratches. Avoid using any harsh chemicals that may compromise the surface of the quartz. Additionally, inspect the tanks periodically for signs of wear, leaks, or any irregularities in its structure. Any minor issues should be addressed immediately to avoid escalation into larger problems. Moreover, keeping an inventory of spare parts can be beneficial for swift replacements as needed, ensuring minimal downtime in laboratory operations.

Safety Considerations in Using Quartz Tanks

When utilizing acid and corrosion resistant quartz tanks in chemical laboratories, it is imperative to prioritize safety to mitigate potential hazards. Quartz tanks are designed to withstand aggressive chemical environments, yet the handling and usage still pose certain risks that must be addressed. Awareness of these hazards is the first step toward ensuring a safe laboratory experience. One key area of concern is the risk of physical damage to the quartz material, which may lead to breakage. Such incidents can result in chemical spills, posing risks not only to laboratory personnel but also to the integrity of the laboratory environment.

Safe handling practices are essential when working with quartz tanks. Laboratory personnel should always wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and lab coats, to protect against chemical exposure. Care should be taken when transporting these tanks; using secondary containment such as trays or specialized carriers can prevent spills if the tank were to tip over. It is crucial to avoid sudden temperature changes that can lead to thermal shock and potential cracking of the quartz material. Therefore, it is advisable to allow the tanks to reach room temperature before introducing them to extreme temperatures.

Moreover, proper usage instructions must be adhered to strictly. This includes adhering to the recommended operating pressures and temperatures of the quartz tanks, as exceeding these limits can compromise their integrity. Before utilizing any chemicals in quartz tanks, a compatibility assessment should be conducted. Certain substances may not react well with quartz or could compromise its durability. Regular inspections of the quartz tanks for any signs of wear, damage, or chemical reactions are also recommended to ensure ongoing safety. By following these safety considerations, laboratories can effectively utilize quartz tanks while minimizing risks associated with chemical handling.

Case Studies and Success Stories

Quartz tanks have increasingly become a staple in chemical laboratories due to their remarkable acid and corrosion resistance. Several case studies exemplify how their implementation has addressed critical challenges in laboratory settings. One notable example can be found in a pharmaceutical laboratory that faced severe corrosion issues with traditional metal storage containers. Frequent breakdowns led to increased operational costs and hindered productivity. The laboratory transitioned to quartz tanks, resulting in a significant reduction in maintenance expenses and an increase in chemical storage longevity.

Another compelling case study involved a university research lab dedicated to analyzing various chemical reactions. This facility often dealt with highly reactive substances that compromised conventional materials. After the installation of quartz tanks, the researchers reported improved safety and efficiency in their experiments. The inert nature of quartz ensured that there were no unwanted reactions with stored chemicals, leading to more reliable data. Moreover, the tanks’ transparency allowed for real-time monitoring of chemical levels, benefiting the research outcomes significantly.

In a third scenario, an environmental testing laboratory faced challenges in storage media for corrosive waste materials. Prior to the implementation of quartz tanks, the lab experienced leakage and contamination instances that posed risks to both personnel and the environment. After switching to quartz tanks designed specifically for corrosive substances, the laboratory achieved compliance with regulatory standards. This transition not only safeguarded the environment but also mitigated risks associated with chemical spills, thus enhancing the lab’s reputation and trustworthiness among regulators.

Overall, these case studies highlight the diverse ways quartz tanks have solved critical problems in laboratory settings. Their acid and corrosion resistant properties have not only improved safety and compliance but have also enhanced the efficiency of laboratory operations across various sectors.

Future Trends in Laboratory Equipment

The landscape of laboratory equipment is poised for significant transformation, particularly with the integration of advanced materials such as acid and corrosion resistant quartz tanks. As technology evolves at a rapid pace, it becomes imperative to examine how innovations in materials science could reshape the future of chemical lab equipment. One notable trend is the increasing adoption of smart technologies. These advancements allow for real-time monitoring of environmental variables, including temperature and chemical concentration, thereby enhancing operational efficiency and safety.

Furthermore, the development of more resilient materials will likely play a pivotal role in laboratory equipment. Innovations in polymers and composite materials could lead to tanks that not only maintain their structural integrity under stringent conditions but are also lighter and more versatile than current offerings. For instance, the introduction of nanotechnology has the potential to optimize the performance of quartz tanks by improving their resistance to chemical attack and thermal stress. This ensures that even in the most corrosive environments, the integrity of the storage system is upheld.

In addition to material advancements, sustainability is becoming a key focus in laboratory equipment. There is a growing emphasis on creating environmentally friendly products that minimize waste and energy consumption. This trend may influence the manufacturing processes of quartz tanks, leading to more eco-efficient production techniques. As laboratories strive to meet stricter environmental regulations, the quest for sustainable materials will drive innovation in the design and function of chemical storage solutions.

Ultimately, the future of laboratory equipment, particularly in the realm of quartz tanks, is likely to be characterized by smarter technologies, advanced materials, and a commitment to sustainability. As the demands of scientists and industry professionals evolve, so too will the capabilities of chemical lab equipment, creating a more efficient and safer working environment.