Introduction to Quartz Sleeves

Quartz sleeves serve as critical components in ultraviolet (UV) lamps and disinfection systems, playing an essential role in facilitating efficient UV light transmission. These sleeves are typically crafted from high-purity quartz glass, which is specifically engineered to allow optimal passage of UV radiation. The use of quartz as the primary material is motivated by its excellent transmission properties, coupled with its ability to withstand the high temperatures involved in UV lamp operation.

In UV disinfection processes, the effectiveness of the UV light in inactivating microorganisms is significantly influenced by the quality of the quartz sleeves. A well-manufactured sleeve can ensure that maximum UV exposure is achieved, thus enhancing the efficacy of the disinfection process. Furthermore, quartz sleeves protect the UV lamp from environmental factors such as dust, moisture, and chemicals, which can compromise its performance and longevity. They also prevent physical damage to the lamp, thereby reducing maintenance costs and downtime.

Importantly, the operational integrity of UV lamps and disinfection systems hinges on the condition and quality of these sleeves. As they age or are subjected to harsh conditions, the transparency and structural integrity of quartz sleeves can deteriorate. This deterioration can lead to decreased UV transmission and increased energy consumption as the system struggles to maintain effective disinfection levels. Regular monitoring and timely replacement of quartz sleeves are thus advisable to sustain optimal performance in UV applications.

In summary, quartz sleeves are indispensable in the realm of UV lamps and disinfection systems, serving not only to facilitate UV light transmission but also to safeguard the lamp itself. Their impact on the efficiency and operational life of UV technology underscores the importance of quality materials and maintenance practices in the field of disinfection.

The Role of UV Lamps in Disinfection Systems

Ultraviolet (UV) lamps serve a vital function in modern disinfection systems, particularly by utilizing UV-C light to eliminate harmful pathogens. The germicidal properties of UV-C light, which lies within the wavelength range of 200 to 280 nanometers, enable it to disrupt the DNA or RNA of microorganisms, preventing their replication and rendering them inactive. This remarkable capability makes UV lamps an essential component in various applications, including water purification, air sterilization, and surface disinfection.

The mechanism through which UV-C light operates is well-documented in scientific literature. When microorganisms are exposed to this wavelength of UV light for a specific duration, the energy absorbed leads to the formation of thymine dimers in DNA, which ultimately hinders the organism’s ability to reproduce. Consequently, even at low concentrations, UV-C can effectively control the spread of bacteria, viruses, and mold spores, making it a highly efficient solution for achieving sanitary conditions across several sectors.

An integral part of optimizing UV lamps in disinfection systems is the use of quartz sleeves. These sleeves provide essential protection for the UV bulb while allowing the passage of UV radiation needed for disinfection. Made from high-purity quartz glass, they not only safeguard the lamp from environmental pollutants and damage but also enhance the lamp’s performance by ensuring maximum UV output. Such efficiency is pivotal in maintaining treatment effectiveness, particularly in critical applications such as medical facilities and food processing plants.

Incorporating UV lamps into disinfection systems represents a proactive approach toward ensuring cleanliness and safety. Their effectiveness is significantly augmented by the strategic use of quartz sleeves, solidifying their place as essential elements in the battle against pathogens.

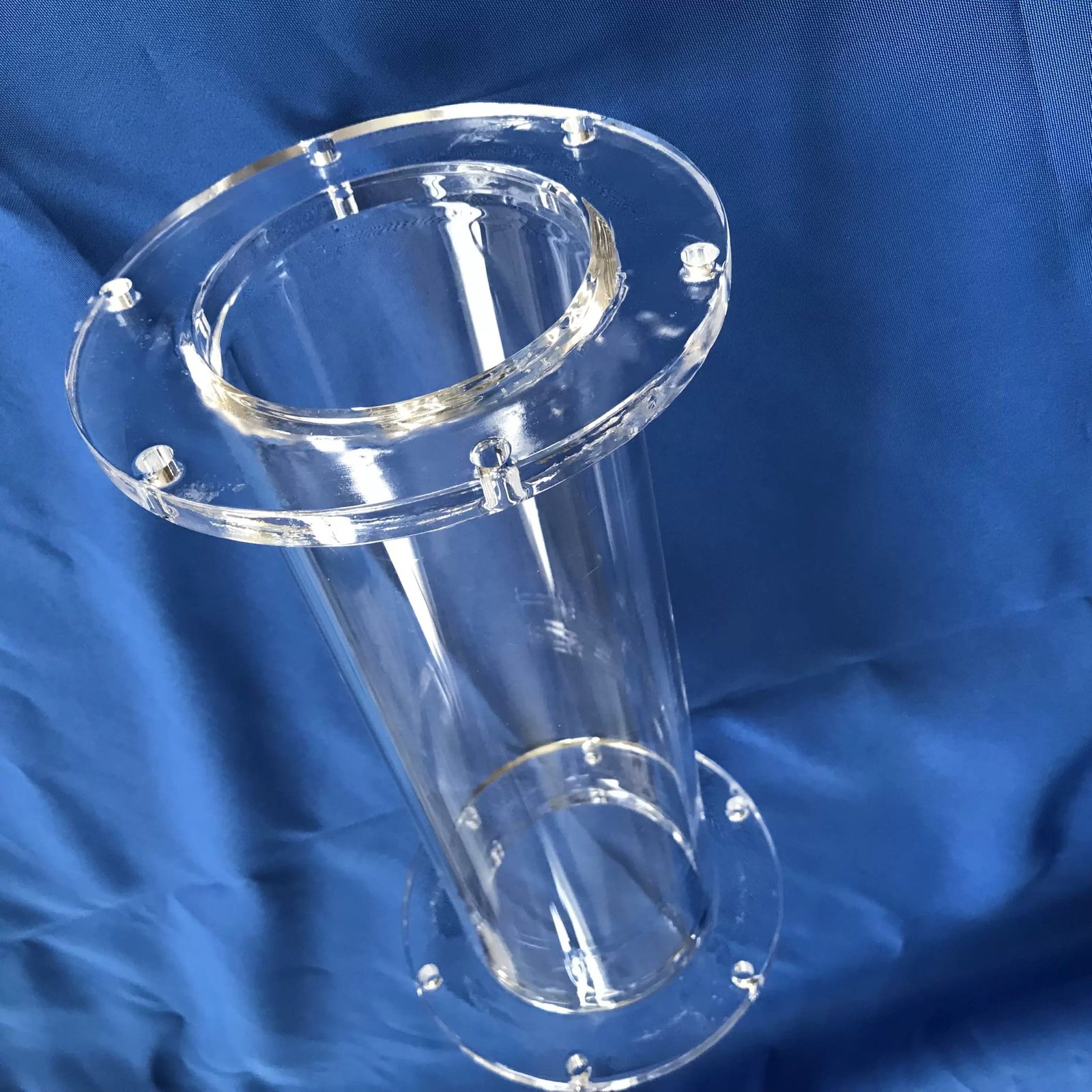

Custom Quartz Sleeves: Why Customization Matters

In the world of UV lamps and disinfection systems, the importance of customization in quartz sleeves cannot be overstated. Custom quartz sleeves offer distinct advantages over standard options, primarily through tailored size, shape, and thickness, which are crucial to meet unique environmental conditions and system requirements. This level of customization enables users to optimize performance and efficiency, critical aspects for any disinfection application.

One of the primary benefits of using custom quartz sleeves is the ability to specify dimensions that perfectly fit your equipment. Standard sleeves may not always accommodate particular setups or installation parameters, leading to compromised performance. By opting for tailored quartz sleeves, users can ensure that the sleeves fit securely, thus minimizing the risk of leaks or exposure to contaminants. This secure fit enhances the overall efficacy of UV lamps, allowing for uniform disinfection across surfaces.

Additionally, the shape of the quartz sleeves can be customized to cater to specific spatial constraints or design preferences. In various applications, the arrangement of components can be quite complex; therefore, having a quartz sleeve tailored to fit seamlessly can simplify installation processes and improve operational reliability. Furthermore, the thickness of the quartz is another significant factor that can be customized. Thicker sleeves typically offer enhanced durability and resistance to environmental stressors, extending the lifespan of the UV lamp and providing cost savings through reduced replacements.

Ultimately, custom quartz sleeves facilitate improved performance in disinfection systems by adapting to varying operational needs. By ensuring that specific sizes, shapes, and thicknesses are utilized, manufacturers can create a more efficient system that meets the demands of diverse applications. Implementing these customized solutions underscores the value of considering specialized options to achieve optimal results in UV disinfection.

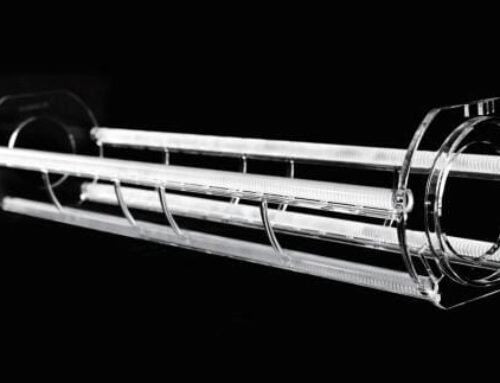

Manufacturing Process of Custom Quartz Sleeves

The manufacturing process of custom quartz sleeves for UV lamps and disinfection systems involves several critical stages that ensure both the quality and functionality of the final product. The first step in this process is the selection of high-quality quartz material. Quartz is chosen for its superior transparency and resistance to UV light, which are vital for the effective operation of UV disinfection systems. Manufacturers often prefer high-purity quartz, which minimizes impurities that can affect performance.

Once the quartz is selected, it undergoes a molding process. This typically involves placing the raw quartz material into a mold that reflects the desired shape and dimensions of the custom sleeve. The molding technique used can vary. For instance, some manufacturers might employ techniques such as centrifugally cast or fused quartz methods. These methods influence the physical properties of the sleeves, affecting their durability and heat resistance, fundamental features for successful applications in disinfection systems.

The next crucial step is the firing process. The molded quartz is subjected to high temperatures, allowing it to achieve the necessary strength and resilience. This step solidifies the shape and enhances the optical clarity of the quartz, ensuring maximum light transmission crucial for UV effectiveness. During this phase, it is also essential to monitor the temperature and duration of firing meticulously, as discrepancies can lead to defects that compromise the sleeves’ performance.

Throughout the manufacturing stages, rigorous quality control measures are implemented. Quality assurance protocols include inspecting the quartz material for defects, as well as conducting tests to assess the sleeves’ structural integrity and UV transmission efficiency. These measures are pivotal to ensuring that the custom quartz sleeves meet the stringent demands of their intended applications in UV disinfection systems, ultimately guaranteeing durability and optimal performance.

Choosing the Right Quartz Sleeve for Your Application

When selecting a custom quartz sleeve for your UV lamp or disinfection system, several critical factors must be considered to ensure optimal performance and efficiency. The first aspect to evaluate is UV lamp compatibility. Quartz sleeves are specifically designed to allow UV light to pass through effectively. Therefore, it is imperative to choose a sleeve that matches the specifications of the installed UV lamp. Different lamps operate at varying wavelengths, and any mismatch might lead to reduced disinfection efficacy or even damage to the equipment.

Another important factor is the environmental conditions in which the quartz sleeve will be used. For instance, if the sleeve will be exposed to high temperatures, it is essential to select a high-temperature resistant quartz material. Likewise, if the application involves exposure to harsh chemicals or corrosive environments, options such as synthetic quartz may be more appropriate due to their enhanced resistance. It is crucial to assess the operational environment to choose a sleeve that not only fits but also endures the necessary conditions.

Specific disinfection needs should also guide your selection process. Different applications may have unique requirements concerning the level of microbial reduction needed, and this is often influenced by the type of fluid or air being treated. For example, potable water treatment will necessitate a different sleeve design compared to industrial wastewater treatment, as these applications may have varying sediment loads and organic materials present. A thorough understanding of the specific disinfection requirements will ensure that the proper quartz sleeve is utilized for maximum effectiveness.

In summary, making an informed decision when choosing a custom quartz sleeve involves assessing compatibility with UV lamps, understanding environmental conditions, and addressing specific disinfection needs. By carefully evaluating these factors, you can select a quartz sleeve that enhances the performance of your UV lamp and meets your application requirements appropriately.

Maintaining and Caring for Quartz Sleeves

Maintaining and caring for quartz sleeves is crucial to ensure their optimal performance and longevity, especially in UV lamps and disinfection systems. Proper care involves regular cleaning, meticulous inspections, and adherence to safe handling practices to prevent damage and contamination.

Cleaning quartz sleeves should be part of a routine maintenance schedule. It is essential to use appropriate cleaning solutions that do not damage the quartz material. A non-abrasive cloth and a gentle, pH-neutral solution are recommended for wiping down the sleeves. Avoid using harsh chemicals or abrasive materials, as these could scratch or degrade the quartz. Additionally, ensure that any cleaning solution is completely rinsed off, as residues can interfere with UV light transmission.

Inspection of quartz sleeves is equally important. Regular visual checks should be conducted to identify any signs of damage, such as cracks, chips, or discoloration. These imperfections can affect the efficacy of UV disinfection and should be addressed promptly. Any noticeable irregularities indicate that the sleeve should be replaced to maintain the system’s functionality. Furthermore, it is advisable to inspect for buildup from water or contaminants, as this layering can obstruct UV light and reduce performance.

Safe handling practices play a significant role in preserving the integrity of quartz sleeves. Always wear appropriate personal protective equipment, such as gloves and safety goggles, when installing or removing sleeves. Handle the sleeves gently to avoid impacts that could lead to fractures. When storing quartz sleeves, place them in a protective case or wrap them to avoid exposure to dust and environmental factors that could harm their quality. By following these maintenance and care guidelines, the performance and durability of quartz sleeves in UV systems can significantly be enhanced.

Common Issues with Quartz Sleeves and How to Resolve Them

Quartz sleeves are essential components in various applications, particularly in UV lamps and disinfection systems. However, like any other equipment, they can experience several common issues that may affect their efficiency and overall performance. Addressing these challenges promptly can ensure that your systems operate optimally.

One prevalent issue is the occurrence of cracks in the quartz sleeve. Cracks can develop due to thermal stress, physical impact, or manufacturing defects. To resolve this issue, it is crucial to inspect the sleeve regularly for any signs of damage. If a crack is detected, the best course of action is to replace the sleeve entirely to avoid compromising the UV light’s effectiveness.

Contamination is another significant concern that can impede the performance of quartz sleeves. Dust, grease, or mineral deposits can accumulate on the sleeve’s surface, leading to reduced UV transmission. This can ultimately affect the disinfection process. Users are encouraged to maintain a regular cleaning schedule, utilizing a soft cloth and appropriate cleaning agents that do not scratch the quartz. Ensuring that the environment around the UV lamp is clean can also help minimize contamination.

Additionally, UV light attenuation can occur if the quartz sleeve becomes compromised or dirty. This reduction in UV intensity can lead to ineffective disinfection. To troubleshoot this issue, it is advisable to measure the UV output using a UV meter before and after cleaning the sleeve. If the attenuation persists despite adequate maintenance, replacing the quartz sleeve may be necessary.

By being aware of these common issues, users can take proactive steps to mitigate risks and guarantee that their custom quartz sleeves function at optimal levels. Regular inspection, maintenance, and timely replacement when needed are essential practices for ensuring the reliability of UV lamps and disinfection systems.

Future Trends in Custom Quartz Sleeves Technology

The field of custom quartz sleeves for UV lamps and disinfection systems is rapidly evolving, driven by advancements in technology and an increasing demand for enhanced disinfection solutions. In recent years, significant innovations have emerged in materials used for manufacturing quartz sleeves. Researchers are exploring alternative composites that offer higher UV transmission rates and greater durability compared to traditional quartz glass. For instance, the introduction of modified silica materials is showing promise in developing sleeves that can withstand higher temperatures while maintaining their optical clarity.

Coatings play a critical role in enhancing the functionality of quartz sleeves. New developments in nanotechnology have paved the way for the application of advanced coatings that repel contaminants and resist degradation from UV exposure. These coatings not only protect the quartz structure itself but also ensure the effectiveness of the UV lamps by minimizing scattering and reflection losses. By incorporating anti-fogging and hydrophobic coatings, manufacturers are addressing common issues that reduce the efficiency of UV disinfection systems, thus extending the service life of the sleeves.

Additionally, design innovations are also poised to reshape the landscape of custom quartz sleeves. The integration of modular designs allows for easier replacement and maintenance, reducing downtime in systems that rely on continuous disinfection cycles. Furthermore, advancements in 3D printing technology provide manufacturers with the capability to create custom shapes and sizes that meet specific application requirements—an approach that was previously limited by traditional manufacturing techniques.

As the demand for effective disinfection methods continues to grow, understanding the importance of these emerging trends in quartz sleeve technology will be crucial. The combination of improved materials, advanced coatings, and innovative designs promises to enhance the performance and lifespan of UV lamps and disinfection systems, paving the way for future applications across various industries.

Conclusion: The Importance of Customized Solutions in UV Disinfection

In the realm of UV disinfection, selecting the right components is crucial to achieving optimal performance. Custom quartz sleeves are integral to the effectiveness of UV lamps, serving as protective encasements that enhance the transmission of ultraviolet light. These tailored solutions not only improve the durability of UV systems but also significantly increase their efficiency in pathogen elimination. By ensuring that the UV light is concentrated and adequately directed, custom quartz sleeves can maximize the germicidal effects of disinfection processes.

One of the primary advantages of custom quartz sleeves lies in their ability to be designed according to specific operational requirements. Factors such as lamp type, system configuration, and application can influence the design, thereby optimizing the disinfection effectiveness. This level of customization enables users to address unique challenges, particularly in specialized environments where standard solutions may fall short. Tailored quartz sleeves can help mitigate issues like fouling, reduce maintenance efforts, and extend the overall lifespan of UV lamps.

Moreover, investing in customized quartz sleeves paves the way for enhanced performance metrics, such as improved energy efficiency and reduced operational costs. For businesses and institutions relying on UV disinfection systems, these benefits can lead to significant long-term savings and more reliable infection control. Therefore, stakeholders in various sectors—from water treatment plants to healthcare facilities—should carefully evaluate the option for custom solutions, as they can greatly influence the effectiveness of UV disinfection practices.

Ultimately, understanding the role of custom quartz sleeves in UV disinfection processes is essential for making informed decisions. Those seeking to boost the efficacy of their disinfection systems should weigh the advantages of customization seriously, as it presents a viable path toward enhancing overall performance and achieving superior sanitation results.