Introduction to Quartz Glass

Quartz glass, a silica-based material, is renowned for its exceptional properties that make it an ideal choice in various applications, particularly in infrared (IR) and ultraviolet (UV) systems. One of its most prominent advantages is its impressive thermal resistance, allowing quartz glass to withstand extreme temperatures without compromising its structural integrity. This characteristic is essential for applications where thermal stability is crucial, ensuring longevity and reliability in demanding environments.

Another significant property of quartz glass is its low thermal expansion coefficient, which minimizes the risk of thermal shock during rapid temperature changes. This feature is vital in industrial and scientific settings, where sudden shifts in temperature can lead to material failure. Furthermore, quartz glass demonstrates excellent optical clarity, effectively transmitting light with minimal distortion. This makes it particularly valuable for optical components in infrared and UV systems, as the transparency of quartz allows for clear imaging and accurate measurements.

The unique composition of quartz glass enables it to selectively transmit specific wavelengths of light while simultaneously blocking others. This feature is particularly beneficial for infrared and UV applications where precise wavelengths are necessary for effective functionality. For instance, in UV sterilization systems, quartz glass can facilitate the transmission of ultraviolet light, ensuring that harmful microorganisms are effectively eradicated, while blocking any unnecessary wavelengths that could lead to inefficiency.

In conclusion, the remarkable properties of quartz glass—such as high thermal resistance, low expansion coefficients, and outstanding optical clarity—position it as the material of choice for infrared and UV systems. Its ability to transmit specific wavelengths while providing durability and stability underscores its critical role in a range of scientific and industrial applications.

The Importance of Infrared Systems

Infrared systems play a pivotal role in a multitude of industries, facilitating a wide range of applications from telecommunications to biomedical advancements. These systems utilize infrared technology to effectively transmit data, monitor conditions, and provide crucial insights that enhance operational efficiency. The significance of infrared systems is underscored by their ability to operate beyond the visible spectrum, offering unique advantages in various fields such as security, medicine, and environmental monitoring.

In telecommunications, infrared systems are employed for high-speed data transmission, allowing for enhanced communication capabilities, especially in wireless setups. The use of infrared light significantly reduces interferences common in radio frequency systems, thereby improving the reliability of data transfer. This aspect becomes particularly critical as the demand for faster and more dependable communication networks continues to grow, making infrared technology an essential component in modern telecommunications infrastructure.

In the biomedical field, infrared systems are utilized in various diagnostic and therapeutic applications. For instance, infrared imaging techniques enable healthcare professionals to detect abnormalities in tissues non-invasively. Furthermore, the ability of infrared systems to penetrate biological tissues allows for precise monitoring of physiological processes. This capacity not only enhances diagnostic accuracy but also facilitates timely intervention, ultimately improving patient outcomes.

The materials used in infrared systems, such as quartz glass domes and lenses, are critical for maintaining efficiency and performance. Quartz is favored for its superior optical properties, which allow for minimal absorption and maximum transmission of infrared light. This characteristic ensures that the systems function optimally, providing reliable results across different applications. Thus, the choice of materials is not merely a technical specification but a significant factor influencing the overall effectiveness of infrared systems.

Understanding UV Systems

Ultraviolet (UV) systems play a pivotal role across various industries, demonstrating their versatility in applications such as industrial curing, sterilization, and phototherapy. The fundamental principle of these systems lies in their ability to emit UV radiation, which can effectively initiate chemical reactions, disinfect surfaces, and promote the healing process in medical treatments.

In industrial settings, UV systems are extensively used for curing inks, coatings, and adhesives. The ability of UV light to rapidly cure materials enhances production efficiency, making it a preferred technology in printing and manufacturing. UV curing methods have significantly reduced drying times, making them essential for high-speed applications. Furthermore, the efficiency of these systems relies heavily on the quality of the materials used, especially in terms of light transmission and resistance to UV-induced degradation.

In the realm of sterilization, UV systems offer a non-chemical means to eliminate pathogens in water treatment facilities and surface disinfection practices. Through the effective emission of UV-C light, which ranges from 200 to 280 nanometers, these systems can disrupt the DNA of microorganisms, rendering them unable to reproduce. This property has made UV sterilization increasingly popular in healthcare settings, where maintaining hygiene is critical.

Phototherapy is another significant application of UV systems, particularly in dermatology. UV light has been employed in the treatment of skin conditions such as psoriasis and eczema, where controlled exposure promotes healing. In this context, the ability of the equipment to deliver precise wavelengths is crucial, underscoring the importance of using high-quality materials for optimal performance.

The choice of materials in UV systems is essential, and quartz glass stands out due to its superior transmission capabilities. Unlike conventional glass, quartz glass allows for the effective passage of UV radiation while exhibiting excellent resistance to thermal and mechanical shocks, ensuring longevity and durability in challenging operating conditions. Its unique properties make quartz glass indispensable for optimizing the performance of UV systems.

Manufacturing Processes for Quartz Glass Domes and Lenses

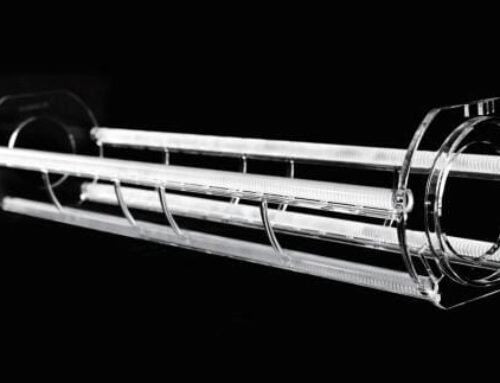

The manufacturing of quartz glass domes and lenses is a process that involves several intricate techniques to produce high-quality components suitable for infrared and ultraviolet (UV) systems. One primary method employed is the molding technique, which allows manufacturers to form quartz glass into specific shapes. In this process, finely ground quartz is mixed with a binding agent and then placed in a mold. Once heated, the material softens and takes on the desired form, creating precise and uniform parts that are vital in optical applications.

Another prevalent technique is blowing, which is particularly beneficial for creating hollow or spherical quartz glass components. During this process, a molten glass parison is inflated using air, allowing it to expand into the necessary shape. Blowing requires significant skill and experience to ensure that the resulting glass is uniform and free from defects. This method is not only effective for producing lenses but also allows for unique designs necessary for specific optical requirements.

Precision machining further enhances the manufacturing process by ensuring that the quartz glass components meet exacting specifications. This technique often involves cutting, grinding, and polishing glass to achieve the desired dimensions and surface finish. Advanced machinery is employed to carry out these tasks with high precision, ensuring that the optical properties of the quartz are maintained. Quality control measures are essential throughout the manufacturing process to verify that the quartz glass domes and lenses adhere to industry standards. Tests may include checking for clarity, refractive index, and resistance to thermal shock, ensuring they are fit for their intended applications in infrared and UV systems.

Benefits of Using Quartz Glass in Infrared and UV Systems

Quartz glass is increasingly recognized as a preferred material for infrared and ultraviolet systems due to its distinctive properties that significantly enhance system performance. One of the primary advantages of quartz glass is its high purity. Unlike many other optical materials, quartz has minimal contaminants, which contributes to its exceptional transmission capabilities across a broad spectrum of wavelengths. This purity ensures that the light passing through the glass is not distorted or absorbed, thus ensuring efficiency in applications that rely on precise wavelength performance.

Another notable benefit of quartz glass is its thermal stability. Quartz can withstand extreme temperatures without degrading, making it ideal for environments where high heat may pose a challenge to standard glass or plastics. This durability not only allows quartz glass to maintain its integrity under intense operational conditions but also extends the lifespan of the systems utilizing it. In applications where temperature fluctuations are common, quartz glass remains a reliable component, significantly reducing the risk of system failure.

Additionally, quartz glass possesses exceptional optical properties, notably high transmissivity and low refractive index across both infrared and ultraviolet wavelengths. This optical clarity allows for minimal scattering and reflection losses, which can enhance the overall performance of optics in various applications, from scientific research to industrial processes. The ability to handle harsh wavelengths without compromising performance is an invaluable advantage that further solidifies quartz glass as the material of choice in these specialized systems.

In summary, the use of quartz glass in infrared and UV systems offers numerous benefits including its high purity, impressive thermal stability, and superior optical properties. These qualities not only enhance system performance but also ensure longevity and reliability that other materials may struggle to provide.

Maintenance and Care for Quartz Glass Components

Maintaining quartz glass domes and lenses is crucial for ensuring optimal performance in infrared and ultraviolet systems. Due to their inherent optical clarity and high-temperature resistance, quartz glass components require specific care to avoid degradation and preserve their functionality. Regular maintenance and proper handling techniques can help prevent scratches and breakage, prolonging the lifespan of these critical components.

When it comes to cleaning quartz glass, it is recommended to use a fiber-free cloth or an anti-static cleaning cloth. These materials are designed to remove dust and debris without leaving fibers behind, which can scratch the surface. For more stubborn residues, a solution of distilled water and isopropyl alcohol may be used. It is important to apply the cleaning solution to the cloth first rather than directly onto the quartz surface, as this prevents excess liquid from entering any mechanical parts attached to the component.

Proper handling of quartz glass is also essential to avoid damage. Wear lint-free gloves while handling lenses or domes to eliminate the risk of fingerprints or oils transferring onto the surface. Furthermore, always handle the components by their edges to minimize the chance of applying pressure to the central area, which is typically more susceptible to fractures.

Storage is another critical aspect of maintaining quartz components. When not in use, quartz glass lenses should be stored in a dedicated, cushioned case specifically designed to prevent movement and impact. Avoid stacking multiple components on top of one another, as this can lead to scratching or, in worst-case scenarios, breakage. Keeping quartz glass domes and lenses in controlled environments, free from extreme temperature fluctuations and humidity, will further ensure their longevity and optical integrity.

Challenges and Limitations of Quartz Glass

While quartz glass presents a myriad of advantages for infrared and UV systems, it also poses several challenges and limitations that should be acknowledged. One of the primary concerns surrounding quartz glass is its cost. Compared to other materials such as borosilicate glass or plastics, quartz glass can be significantly more expensive. This heightened cost may deter some users, particularly in budget-sensitive projects or applications. Additionally, the fabrication process of quartz glass demands precise techniques, which may raise manufacturing costs further.

Another challenge lies in the susceptibility of quartz glass to thermal shock if not managed appropriately. While quartz glass generally exhibits high thermal resistance, rapid temperature changes can lead to stress fractures. This peril necessitates careful handling during installation and operation to maintain the integrity of the components. Users must therefore take necessary precautions when integrating quartz glass into systems subjected to fluctuating temperatures or abrupt thermal transitions.

Moreover, the performance of quartz glass can be limited under extreme environmental conditions. For instance, in applications involving aggressive chemicals, quartz glass may not provide the necessary resistance. Depending on the specific chemical composition and environmental exposure, degradation could occur, leading to a compromise in its protective properties. Furthermore, its transparency characteristics may diminish in environments with high particulate matter or prolonged exposure to UV radiation, affecting lens performance over time.

Ultimately, recognizing these challenges and limitations is crucial for anyone considering the use of quartz glass in infrared or UV applications. With careful assessment and strategic planning, it is possible to mitigate these concerns, ensuring optimal performance and longevity of quartz glass components.

Future Trends in Quartz Glass Applications

The utilization of quartz glass in infrared and UV systems is anticipated to evolve significantly over the coming years. As industries strive to enhance efficiency and performance, several emerging trends are coming to the forefront, poised to redefine the landscape of quartz glass applications. One of the most notable advancements is the development of high-purity quartz glass, which is engineered to minimize impurities that can impair optical performance. This trend is crucial for industries that rely heavily on precision, such as semiconductor manufacturing, where even minute deviations can lead to significant operational disruptions.

In addition to high-purity offerings, innovations in manufacturing techniques are also gaining traction. For instance, advancements in molding and shaping technologies are enabling the production of more complex and customized quartz glass components. These innovations allow for greater versatility in design, paving the way for novel applications across a variety of sectors, including medical devices, telecommunications, and aerospace. The ability to create intricate geometries not only enhances functionality but also increases the potential market for quartz glass products.

Furthermore, the integration of smart technology with quartz glass is underway. Manufacturers are exploring the incorporation of sensors and other interactive elements within quartz glass products. This trend aims to increase the functionality of standard quartz glass lenses and domes, providing real-time data and feedback that can enhance operational effectiveness in UV and infrared systems. Such integration may lead to the development of advanced monitoring systems in agriculture, healthcare, and environmental management, contributing to improved resource management and sustainability.

As research and innovation continue, it is evident that the future holds promising prospects for quartz glass applications. The ongoing exploration of new technologies, coupled with the fine-tuning of existing materials, will not only expand the existing market horizons but also elevate quartz glass’s significance in a myriad of emerging fields.

Conclusion

In conclusion, the discussion surrounding quartz glass domes and lenses highlights their critical role in enhancing the functionality and efficiency of infrared and UV systems. Throughout this guide, we have explored the unique properties of quartz glass, such as its excellent transmission capabilities, thermal stability, and resistance to high radiation levels. Each characteristic plays an essential part in making quartz glass the preferred material for applications where traditional glass would fail to meet the stringent requirements necessary in these advanced technologies.

Furthermore, the versatility of quartz glass allows it to be customized for various specifications, ensuring that it aligns perfectly with the unique needs of different industries. From laboratory setups to manufacturing processes, the incorporation of quartz glass domes and lenses can significantly enhance performance, thus improving overall outcomes. The ability to withstand extreme conditions while maintaining optical clarity is invaluable for practitioners in fields where precision is paramount.

As we reaffirm the importance of these components, it is crucial for readers to consider quartz glass for their specific applications in infrared and UV systems. Consulting with experts in the field will provide insights into best practices and optimal solutions tailored to individual needs. Specialist advice can aid in selecting the correct type of quartz glass based on factors such as the application environment, temperature ranges, and exposure to certain wavelengths of light.

To sum up, the valuable attributes of quartz glass, combined with professional guidance, empowers users to make informed decisions and enhance the effectiveness of their infrared and UV systems. The benefits of utilizing quartz glass domes and lenses cannot be overstated, and they represent a vital investment for any organization dedicated to advancing technology and achieving excellence in their respective fields.