Quartz Tanks: Understanding the Differences in Uses and Designs

Quartz Tanks: Understanding the Differences in Uses and Designs

Quartz tanks, including Quartz Cleaning Baths and Quartz Square Tanks, serve distinct purposes due to their differences in design and application. This article explores their key variations in material properties, uses, and structural features.

1. Definition and Use

Quartz Cleaning Bath:

This specialized container is designed for chemical cleaning, widely used in industries like semiconductors, optics, and laboratories. It is specifically utilized for cleaning high-purity substances or sensitive materials in environments requiring resistance to strong acids and alkalis. These baths are commonly employed in the cleaning of silicon wafers, semiconductor devices, and other precision electronic components, with the ability to withstand high temperatures and corrosive chemicals.

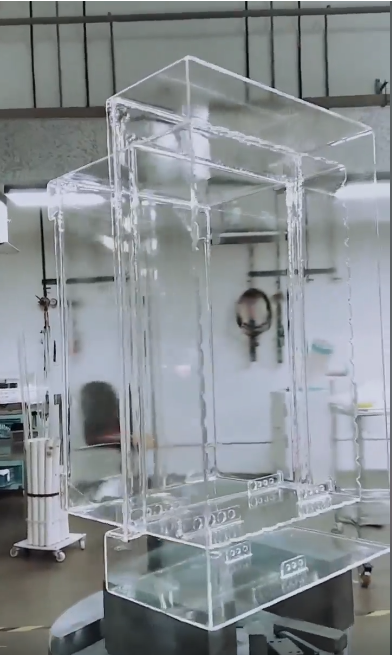

Quartz Rectangular Tank (Square Tank):

This versatile container is typically used in experiments, optical equipment, or for storing high-purity liquids. Its applications range from liquid storage to being part of specific physical and chemical experiments. Due to its excellent light transmittance, square tanks are frequently used in optical experiments, such as light transmittance testing.

2. Material Characteristics

Similarities:

Both types are made from high-purity quartz, offering key properties like high temperature resistance, chemical corrosion resistance, and excellent light transmittance.

Differences:

While made from the same material, cleaning baths are usually thicker and heavier, designed to endure continuous chemical reactions and high temperatures. Square tanks focus more on volume capacity and light transmittance, making them suitable for storage and optical applications.

3. Shape Design

Cleaning Baths:

These baths typically have an open, deep structure, often rectangular or square, with design considerations that make them easy to operate. The depth and size are optimized for various cleaning tasks, particularly in high-temperature environments.

Square Tanks:

These tanks have a standard rectangular or square shape, with flat sides and bottoms. Their design focuses on dimensional accuracy, balance, and storage capacity, making them ideal for laboratory use and optical testing.

4. Main Use Differences

Cleaning Baths:

These baths are specially designed for high-temperature and high-pressure cleaning processes, particularly when dealing with sensitive materials like semiconductors. They are essential in semiconductor manufacturing, handling acids, alkalis, and other chemical solvents for thorough cleaning.

Square Tanks:

More versatile in their applications, these tanks are often used as laboratory storage containers, for optical testing, or for storing special liquids. Their transparency and heat resistance also make them suitable for optical experiments, such as light transmission tests.