Quartz reactor is a highly specialized experimental equipment. Due to its high temperature resistance, corrosion resistance and high purity, it is widely used in fields that require chemical reactions under extreme conditions. The following is a detailed introduction to quartz reactor:

1. Material properties

Quartz reactor is made of high-purity quartz glass. Quartz glass is a special glass composed of silicon dioxide (SiO₂) and has many superior physical and chemical properties:

High temperature resistance: The softening point of quartz glass is around 1700°C. It can work for a long time under high temperature conditions above 1000°C without deformation or damage, and is suitable for high temperature reactions.

Corrosion resistance: Quartz glass has extremely high tolerance to most acids, alkalis and salt chemicals, and is particularly suitable for use in corrosive environments without affecting the results of chemical reactions.

High purity: Quartz glass has extremely high purity and is usually used under high-purity reaction conditions to avoid foreign impurities affecting experimental results. It is widely used in the semiconductor and optoelectronic fields.

Excellent light transmittance: Quartz glass has a high transmittance to ultraviolet, infrared and visible light. This feature allows the operator to directly monitor the reaction process through the observation window or transparent reactor.

2. Main applications of quartz reactors

Quartz reactors are widely used in the following industries:

Chemical industry: used for high-temperature synthesis, catalytic reaction or corrosive gas treatment, especially for processes that require extremely high chemical stability during the reaction.

Pharmaceutical industry: In the production process, quartz reactors are often used in the synthesis of drugs and the preparation of fine chemicals due to their high purity and pollution-free characteristics.

Semiconductor and optoelectronics field: In semiconductor production, quartz reactors can ensure an ultra-pure environment to prevent external contaminants from affecting the wafer production process.

Laboratory research: Quartz reactors are often used in experiments that require precise temperature control and high-purity environment, especially experiments under high temperature, high pressure and highly corrosive conditions.

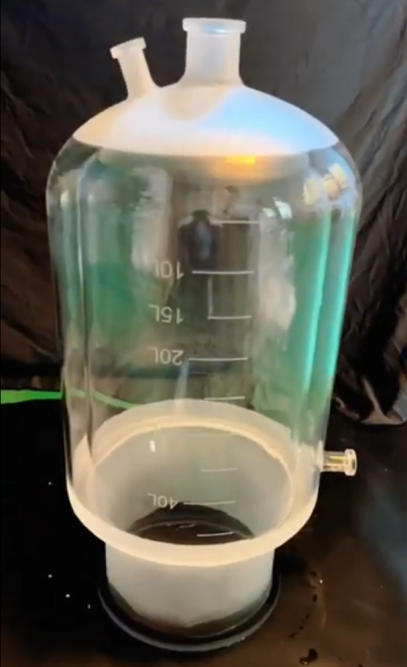

3. Design and structure

The design of a quartz reactor is usually determined according to the specific requirements of its application. Common structures include:

The reactor body: The main part is made of quartz glass, which has the characteristics of high temperature resistance, corrosion resistance and transparency.

The reactor cover and seal: In order to ensure the sealing of the reaction under high temperature or high pressure conditions, the reactor cover is usually made of a material that matches the reactor body, and the sealing system may use high temperature resistant rubber or fluoroplastics and other materials.

Stirring system: Some quartz reactors are equipped with a stirring device to evenly mix the reactants during the reaction.

Heating and temperature control device: Quartz reactors are usually equipped with electric heaters or external heating systems, and connected to temperature control devices to accurately control the reaction temperature.

Pressure monitoring and exhaust port: In high pressure reactions, quartz reactors may be designed with pressure gauges and safety exhaust valves to ensure experimental safety.

4. Use and maintenance

Operation precautions: Since quartz reactors are usually used under high temperature or high pressure, sudden temperature changes should be avoided during operation to prevent the quartz glass from breaking due to thermal expansion and contraction. In addition, the surface of the reactor should be kept away from hard objects or scratches, as these damages may reduce its strength.

Cleaning and maintenance: The quartz reactor should be cleaned promptly after use to avoid long-term corrosion of the reactor by residual chemicals. Acidic or alkaline solutions can be used for cleaning, but hard brushes should be avoided to prevent scratching the glass surface.

5. Advantages

Excellent chemical inertness: Quartz glass does not react with most chemicals, ensuring that the chemical reaction is not disturbed by external factors.

High transparency: During the experiment, the operator can directly observe the dynamic changes of the reaction, which is especially suitable for experiments that need to monitor the reaction process.

Strong thermal stability: Quartz reactors maintain excellent performance at extreme temperatures and are not prone to expansion or cracking.

6. Customization

Quartz reactors can be customized according to the specific needs of customers, including capacity, shape, agitator configuration, heating method, etc., to meet the requirements of different experiments or industrial processes.