Introduction to Quartz Glass

Quartz glass, a remarkable material derived primarily from silicon dioxide (SiO2), is recognized for its outstanding properties and versatility in various applications. Comprising nearly 99.9% pure silica, quartz glass is well-known for its remarkable chemical stability and thermal resistance, which sets it apart from other glass types. Due to its unique characteristics, it is often utilized in environments that demand high performance and reliability.

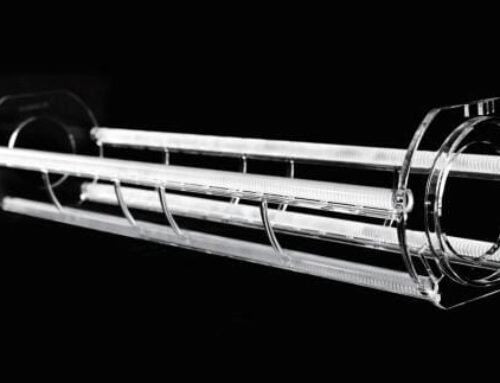

This remarkable material finds extensive use across multiple industries. For instance, in the electronics sector, quartz glass is employed in the production of high-purity components, such as semiconductor wafers and photomasks. Its exceptional transparency across a broad spectrum of wavelengths makes it an ideal choice for optical applications, including lenses and prisms. Furthermore, the scientific community frequently utilizes quartz glass in laboratory equipment, such as cuvettes and reaction vessels, where purity and thermal stability are crucial.

Exploring the properties of quartz glass is vital for several reasons. Understanding its exceptional strength enables designers and engineers to leverage its capabilities in creating durable and reliable products. Additionally, the purity of quartz glass plays a significant role in industries where contamination can significantly affect outcomes, such as pharmaceuticals and biotechnology. Lastly, its UV transparency is particularly advantageous in applications requiring exposure to ultraviolet light, including germicidal lamps and certain photolithographic processes.

In a world increasingly reliant on advanced materials, diving deeper into the properties of quartz glass offers insights that can enhance product development and application efficiency. With its unique composition and extensive range of applications, quartz glass stands out as not only a technical marvel but also a crucial material in various fields.

Understanding the Composition of Quartz Glass

Quartz glass, renowned for its remarkable properties, is primarily composed of silica (SiO2), a naturally occurring mineral essential to its formation. This glass variant, distinguished by its high purity and strength, primarily results from the meticulous combination of silicon and oxygen atoms. The chemical structure of quartz glass is crystalline in nature, allowing it to consistently maintain its integrity across various applications, from high-temperature settings to optical instruments.

The purity of the silica used to create quartz glass plays a pivotal role in determining the material’s overall quality and its subsequent applications. High-purity quartz glass is made from raw quartz grains that undergo extensive purification processes. The reduced presence of impurities not only enhances its optical clarity but also improves its resistance to thermal and mechanical stresses. In contrast, lower-grade quartz glass may include trace elements that can affect its performance, making it unsuitable for specialized applications, such as in semiconductor manufacturing or high-precision optics.

Moreover, the manufacturing techniques employed in producing quartz glass are equally vital in ensuring its quality. Processes such as fusion or melting of silica at elevated temperatures help yield consistently high-purity glasses. The controlled environment in which this occurs prevents contamination and further optimizes the resultant material’s properties. Different grades of quartz glass, classified based on purity levels, cater to a range of industries, including electronics, aerospace, and scientific research.

Ultimately, understanding the chemical composition, particularly the significance of silica, is essential in grasping the various attributes that make quartz glass a unique and indispensable material in modern technology and industrial applications.

The Strength of Quartz Glass

Quartz glass, renowned for its exceptional mechanical strength, presents a compelling material choice in various applications that demand durability and resilience. Compared to traditional glass options, quartz glass exhibits superior structural integrity due to its unique composition and processing methods. While standard glass is primarily comprised of silica mixed with other compounds, quartz glass is made predominantly from fused silica, resulting in a material that is not only stronger but also highly resistant to mechanical stress.

One of the key factors contributing to the strength of quartz glass is its ability to withstand thermal shock. Thermal shock resistance refers to a material’s capacity to endure rapid temperature changes without cracking or breaking. Quartz glass can endure sudden increases in temperature that would typically fracture ordinary glass. This property enables its use in high-temperature environments, making it ideal for laboratory equipment such as beakers, crucibles, and test tubes, where abrupt temperature shifts may occur during experiments.

Moreover, the mechanical strength of quartz glass is significantly enhanced by its low expansion coefficient, which minimizes stress concentrations during thermal cycling. Additionally, quartz glass’s high compressive strength further increases its durability, providing an advantage in industrial applications that require both strength and reliability.

In optics, quartz glass finds extensive application due to its high transmission of ultraviolet (UV) light, coupled with its strength. Sophisticated optical components, like lenses and prisms, benefit from quartz glass’s ability to maintain structural integrity while delivering high-performance results. Consequently, it is increasingly employed in the manufacture of high-quality optical instruments and UV filters.

In conclusion, the strength of quartz glass, characterized by its resistance to thermal shock and mechanical stress, positions it as a superior choice compared to other glass types, particularly in critical applications ranging from laboratory settings to the optics industry.

Purity of Quartz Glass

Purity is a critical factor in the manufacturing of quartz glass, as it directly impacts the material’s performance in various applications. High-purity quartz glass is characterized by minimal impurities, which ensures optimal optical clarity, thermal stability, and mechanical strength. To achieve this level of purity, manufacturers implement rigorous processes that involve sourcing the right raw materials and employing advanced purification techniques.

The initial phase of producing high-purity quartz glass begins with the selection of high-quality quartz feedstock. This raw material undergoes extensive processing to remove contaminants such as metals, alkalis, and other trace elements. One of the commonly used methods is the high-temperature chemical vapor deposition (CVD) technique, which allows for the conversion of silicon compounds into pure quartz through a series of chemical reactions. This process results in a material with over 99.99% purity, making it suitable for demanding applications.

The implications of impurities in quartz glass can be substantial, particularly in fields such as semiconductor fabrication and pharmaceuticals. In semiconductor manufacturing, even minute levels of contaminants can significantly affect the performance of electronic components, leading to reduced efficiency and reliability. Similarly, in the pharmaceutical industry, high-purity quartz glass is essential for maintaining the integrity of sensitive compounds and ensuring accurate results in laboratory settings. Any impurities can introduce variables that compromise the quality of pharmaceuticals, thus making purity a non-negotiable aspect of production.

Moreover, as industries evolve and the demand for high-performance materials increases, the emphasis on the purity of quartz glass is likely to intensify. The advancements in purification technologies will further enhance the optical and functional properties of this versatile material, cementing its role in various high-tech applications.

UV Transparency of Quartz Glass

Quartz glass is renowned for its exceptional ability to transmit ultraviolet (UV) light, which significantly distinguishes it from conventional glass. This remarkable property is largely attributable to the material’s unique molecular structure, which allows UV wavelengths to pass through with minimal absorption or scattering. Compared to standard glass, which can block or attenuate UV radiation, quartz glass offers a clear advantage in various scientific and industrial applications.

One of the primary utilizations of quartz glass’s UV transparency is in the manufacturing of UV lamps. These lamps, which emit UV light for various purposes—including sterilization and disinfection—rely on quartz glass to ensure maximum light output. By facilitating the transmission of UV rays, quartz glass enhances the efficacy of these lamps, making them a preferred choice in medical and laboratory settings where sterilization is of utmost importance. The ability to transmit UV light effectively allows for a more efficient disinfection process, eliminating harmful microorganisms and ensuring a safe environment.

Moreover, quartz glass is extensively utilized in scientific research, particularly in spectrophotometry and chromatography, where precise measurements of UV light are critical. The high level of UV transparency allows scientists to perform analyses without the interference often caused by other materials. This capability is essential for obtaining accurate data and results in various research domains, including chemistry and biology. Furthermore, the stability of quartz glass under UV exposure makes it a reliable option for long-term experiments, offering durability and consistency over time.

In essence, the superior UV transparency of quartz glass not only surpasses the limitations of traditional glass but also opens up a myriad of opportunities for innovation across multiple disciplines. Its roles in UV lamp technology, sterilization methods, and research applications highlight its importance in contemporary science and industry.

Applications of Quartz Glass in Various Industries

Quartz glass, known for its remarkable properties such as high thermal resistance, excellent chemical stability, and significant UV transparency, finds extensive applications across diverse industries. One of the primary sectors that benefit from quartz glass is the telecommunications industry. In this field, the ability of quartz glass to minimize signal loss ensures reliable communication over long distances. Fiber optic cables made from quartz glass efficiently transmit data through light, revolutionizing how information is shared globally.

Another critical domain where quartz glass is indispensable is the electronics industry. Its dielectric properties make it an excellent choice for manufacturing various electronic components, including capacitors and insulators. The ability of quartz glass to maintain functionality under high temperatures and corrosive environments enhances the performance and durability of electronic devices. As technology continues to advance, the demand for materials that can withstand the rigors of modern electronics increases, further solidifying quartz glass’s role in this sector.

Moreover, the medical devices industry leverages the unique characteristics of quartz glass extensively. Its high purity level ensures that medical equipment remains sterile, which is essential in preventing infections during surgical procedures. Quartz glass is utilized in the production of diagnostic equipment and laboratory instruments due to its resistance to thermal shock and chemical interactions. Furthermore, quartz glass’s transparency to UV light aids in various medical applications, such as phototherapy and sterilization.

Finally, quartz glass is pivotal in laboratory equipment. Many scientific instruments, including spectrophotometers and cuvettes, require materials that can provide accurate measurements without interference from the medium itself. The exceptional optical clarity and stability of quartz glass make it an ideal material for such applications. In summary, quartz glass’s unique properties render it essential in telecommunications, electronics, medical devices, and laboratory equipment, making it a versatile material suited for specialized industrial applications.

Comparison with Other Types of Glass

Quartz glass, also known as fused silica, possesses distinct properties that set it apart from other glass types, including soda-lime glass and borosilicate glass. Understanding these differences is crucial for selecting the appropriate glass for specific applications. Generally, soda-lime glass is the most common type of glass, primarily used in containers and windows. It is composed of silica, soda, and lime, making it cost-effective, yet it lacks the high-performance characteristics found in quartz glass.

One of the foremost advantages of quartz glass is its remarkable strength. When subjected to high temperatures, quartz glass maintains its structural integrity much better than soda-lime glass. This leads to enhanced durability, making quartz glass suitable for applications that demand resilience, such as laboratory equipment and optical devices. Conversely, although borosilicate glass offers improved thermal resistance compared to soda-lime glass, it does not match the overall strength and durability of quartz glass.

Purity is another critical factor in glass comparison. Quartz glass is known for its exceptional level of purity, with minimal impurities when compared to other types of glass. This purity contributes to its widespread use in the semiconductor and pharmaceutical industries. In contrast, soda-lime glass typically contains various impurities, which can affect its optical clarity and chemical stability in sensitive environments.

UV transparency further emphasizes the superiority of quartz glass. It allows a broader spectrum of ultraviolet light to pass through, making it indispensable in applications such as spectroscopy and UV curing processes. On the other hand, soda-lime and borosilicate glasses usually attenuate UV light, limiting their usability in scenarios where UV exposure is crucial.

Overall, while each type of glass has its merits, quartz glass stands out for its strength, purity, and UV transparency, making it an ideal choice for specialized applications where conventional glass may fall short.

Future Trends in Quartz Glass Technology

As the demand for high-performance materials continues to grow across various industries, advancements in quartz glass technology have become increasingly prominent. Manufacturers are continually exploring innovative techniques to enhance the production process, leading to more efficient and cost-effective methods. Recent developments include improved melting processes that reduce energy consumption and increase yield, paving the way for greater sustainability in quartz glass manufacturing.

One of the significant trends involves the integration of automation and smart manufacturing technologies into quartz glass production. By employing advanced robotics, artificial intelligence, and Internet of Things (IoT) solutions, companies are aiming to optimize production efficiency and ensure consistent quality control. This transition not only streamlines operations but also minimizes waste, promoting environmentally friendly practices within the industry.

Moreover, research into new applications for quartz glass is expanding rapidly. Industries such as electronics, telecommunications, and biotechnology are recognizing the unique properties of quartz glass, including its remarkable resistance to thermal shock and excellent optical clarity. Innovations like microfluidic devices and advanced optoelectronic components are emerging, driven by the versatility of quartz glass. As these industries evolve, the demand for specialized quartz glass products tailored to specific applications will likely increase.

In addition to advancements in manufacturing techniques and application diversity, there is an increasing emphasis on the use of recycled materials in quartz glass production. Companies are exploring the feasibility of incorporating recycled glass into their processes to reduce environmental impact while maintaining product integrity. This shift toward sustainable practices not only addresses ecological concerns but also enhances the overall brand value of manufacturers committed to responsible production methods.

In conclusion, the future of quartz glass technology is poised for transformative advancements, fueled by innovation in manufacturing processes, sustainable practices, and expanding applications. As these trends continue to evolve, quartz glass will play an increasingly vital role in meeting the diverse needs of modern industries.

Conclusion

In summarizing the essential properties of quartz glass, it is evident that its strength, purity, and UV transparency significantly contribute to its wide array of applications. The unparalleled strength of quartz glass, which surpasses that of many traditional glass materials, enhances its usage in environments where durability is paramount. This property plays a critical role in sectors such as telecommunications, where robustness is necessary for fiber optic applications.

Furthermore, the exceptional purity of quartz glass sets it apart from other materials, making it invaluable in scientific research and semiconductor manufacturing. The low levels of impurities not only ensure optimal performance but also enhance the effectiveness of quartz glass in high-precision environments. This characteristic allows for its application in optics and various high-tech industries, where clarity and purity are essential.

Another significant advantage of quartz glass is its remarkable UV transparency, enabling it to transmit ultraviolet light effectively. This property opens up numerous possibilities for applications in industries such as solar energy, where efficient UV transmission can lead to improved energy absorption. The ability of quartz glass to withstand UV radiation without degrading further substantiates its pivotal role in various technological advancements.

Looking ahead, the future of quartz glass appears promising. As industries continue to evolve, the demand for materials that offer high durability, purity, and UV transparency will likely escalate. Innovations in manufacturing processes may lead to even more advanced forms of quartz glass, expanding its use in sectors such as aerospace, medical devices, and renewable energy. In this ever-growing landscape, quartz glass will undoubtedly remain a fundamental component, driving progress and enhancing technological solutions across multiple disciplines.