Introduction to Laboratory Quartz Instruments

Laboratory quartz instruments encompass a variety of specialized glassware, including beakers, crucibles, and tubes, widely utilized in scientific research and analytical applications. The intrinsic qualities of quartz make it an advantageous choice for these instruments. Its high thermal resistance is paramount, as it can withstand extreme temperatures without deforming or degrading. This property is essential for experiments that involve intense heating or cooling processes, where conventional glass might fail.

Furthermore, quartz exhibits remarkable chemical inertness. It does not react with a wide range of chemicals, which enables scientists to conduct experiments without the concern of altering the results through contamination or interaction with the container. This makes quartz instruments particularly valuable in sensitive analytical applications, such as those involving reactive substances or complex solutions.

Another significant advantage of laboratory quartz instruments is their optical clarity. This property allows for precise analysis of materials, especially in spectroscopy and other light-based techniques. The transparent nature of quartz facilitates the observation and measurement of reactions and changes occurring within the vessel, providing critical data that may be obscured in other types of containers.

In addition to these properties, quartz instruments tend to possess a high level of durability and can endure repeated cycles of heating and cooling without compromising their structural integrity. This reliability reduces the need for frequent replacements, thus optimizing cost-efficiency in laboratory settings. Consequently, laboratory quartz instruments, such as beakers, crucibles, and tubes, have become indispensable tools in various scientific disciplines, including chemistry, biology, and materials science.

The Importance of Customization in Laboratory Instruments

In the realm of scientific research and experimentation, the precision and reliability of laboratory instruments are paramount. Customization plays an essential role in ensuring that instruments like beakers, crucibles, and tubes are tailored to the specific needs of various applications. By providing bespoke solutions, laboratories can enhance their operational efficiency and meet the rigorous demands of diverse scientific endeavors.

The significance of customized laboratory instruments lies in their ability to accommodate varying dimensions, shapes, and material requirements. Different experiments demand specific properties; for instance, a high-temperature crucible might be required for metal testing, while a chemically resistant beaker is essential for conducting corrosive substance reactions. By utilizing custom instruments, researchers can ensure that they have the appropriate tools designed to withstand the conditions of their experiments, leading to improved outcomes.

Moreover, custom quartz instruments lead to a reduction in the risk of contamination and error. Standard equipment may not always provide the necessary compatibility for certain innovative materials or compounds being researched. Custom solutions minimize such risks by allowing researchers to select materials that align closely with their specific project parameters. This not only promotes safety in lab environments but also enhances the integrity of experimental results.

In addition to enhancing accuracy and safety, customized laboratory instruments can significantly contribute to productivity. Researchers are often pressed for time, and having specialized instruments that fit their exact requirements streamlines workflows. This allows scientists to focus on their core research activities rather than being hindered by tools that do not fully support their methodologies. Ultimately, the importance of customization in laboratory instruments like quartz beakers, crucibles, and tubes offers a unique solution to the complex challenges faced by modern scientific professionals.

Types of Quartz Laboratory Instruments

Laboratory quartz instruments have gained significant prominence in various scientific fields due to their excellent thermal stability, chemical resistance, and optical properties. This section will introduce three primary types of quartz laboratory instruments: beakers, crucibles, and tubes, exploring their design, functionality, and applications within laboratory settings.

Quartz beakers are essential laboratory tools utilized for mixing, heating, and holding liquids. They are typically designed with a wide mouth and a spout for easy pouring. Unlike traditional glass beakers, quartz beakers withstand higher temperatures and exhibit better resistance to chemical corrosion, making them ideal for experiments involving harsh chemicals. For example, in chemical synthesis, quartz beakers often serve as reaction vessels due to their ability to endure extreme conditions without compromising structural integrity.

Another vital instrument in quartz laboratories is the crucible, which is primarily employed for high-temperature applications such as melting and holding solid samples. Quartz crucibles are characterized by their durability and ability to resist thermal shock, which is critical when dealing with extreme temperature variations. In metal processing and ceramic applications, quartz crucibles are favored for their purity and minimal contamination risk, which is essential for achieving accurate and reproducible results during high-temperature experiments.

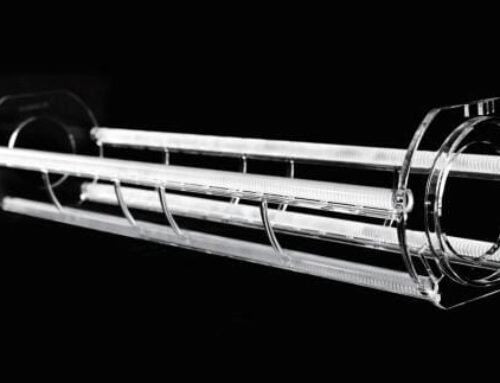

Finally, quartz tubes play a crucial role in various analytical techniques, particularly in spectroscopy and chromatography. These tubes, specially designed for holding gases or liquids, ensure minimal interference with the transmitted light, enhancing the accuracy of measurements. Furthermore, quartz tubes can withstand high pressures and temperatures, rendering them suitable for advanced applications like gas chromatography, where consistent results are paramount.

In summary, quartz laboratory instruments such as beakers, crucibles, and tubes offer remarkable benefits in terms of thermal stability, chemical resistance, and optical clarity. Their specialized designs cater to specific laboratory needs, making them indispensable tools in scientific research and experimentation.

Quartz Beakers: Specifications and Applications

Quartz beakers are an essential tool in various laboratory settings, known for their unique specifications that cater to the demands of scientific experimentation. Typically constructed from high-purity quartz glass, these beakers exhibit exceptional advantages over traditional glass beakers, particularly in terms of heat resistance and chemical durability. The heat resistance of quartz allows these beakers to withstand extreme temperatures, making them suitable for processes involving boiling or high-temperature reactions.

In terms of size, quartz beakers come in a variety of capacities, often ranging from 50 mL to several liters. This diversity in size facilitates their use in multiple applications, from small-scale experiments to large-scale industrial processes. Additionally, the clarity of quartz makes it easy for researchers to observe chemical reactions without interference, an important feature in precise experimental work.

The applications of quartz beakers are vast and varied. They are frequently employed in analytical chemistry, where precise measurements and chemical purity are paramount. For instance, quartz beakers are often utilized in spectrophotometric analysis, where clarity and lack of impurities can significantly affect the accuracy of readings. Moreover, these beakers are instrumental in the preparation of chemical solutions and in carrying out titrations, where consistent results are crucial.

Another area where quartz beakers prove indispensable is in high-temperature synthesis processes, such as those encountered in materials science. Their ability to handle thermal stress without the risk of thermal shock makes them ideal for reactions that require the simultaneous heating of materials in a controlled environment. Such characteristics ensure that quartz beakers are not only durable but also enhance the reliability of the results obtained from experiments conducted within them.

Understanding Quartz Crucibles

Quartz crucibles are specialized containers widely utilized in high-temperature applications, particularly in the fields of material analysis and laboratory processes. Renowned for their exceptional thermal stability, these crucibles can withstand extreme temperatures, often exceeding 1000 degrees Celsius, making them ideal for various metal melting procedures and chemical reactions. The unique properties of quartz, such as its low thermal expansion coefficient and high purity levels, ensure minimal reaction with the materials being processed, thus enhancing the reliability of results obtained in both research and industrial settings.

One of the primary uses of quartz crucibles is in the melting of metals and alloys. When subjected to intense heat, these crucibles provide an environment conducive to achieving the desired melting point without compromising the quality of the molten material. This is critical, especially in metallurgy, where precision is paramount. Additionally, quartz crucibles are often used in analytical chemistry for procedures like ignition, as they do not introduce contaminants into the samples, allowing for accurate analysis of chemical compounds.

Moreover, the importance of custom quartz crucibles cannot be overstated. Laboratories often require crucibles tailored to specific experiments or designs to facilitate enhanced efficiency. Custom crucibles can be manufactured in varying sizes and shapes to accommodate different quantities and forms of materials, enabling researchers to optimize their processes. The adaptability of custom quartz crucibles also extends to their application in diverse industries, including pharmaceuticals, electronics, and materials science.

In conclusion, quartz crucibles play a pivotal role in facilitating high-temperature applications and material analysis. Their refined properties make them indispensable in laboratory settings, where custom designs further enhance operational efficiency and reliability. As industries continue to evolve and demand precision, the relevance of quartz crucibles in scientific innovation remains undeniably significant.

Quartz Tubes: Versatility in Applications

Quartz tubes are essential components in a broad range of laboratory applications, valued for their unique properties and versatility. Made from high-purity quartz, these tubes exhibit exceptional thermal resistance and chemical durability, making them suitable for various uses, including gas analysis, chemical reactions, and as integral parts of analytical instruments. Their ability to withstand high temperatures without deformation or degradation sets quartz tubes apart from alternatives such as glass or plastics.

In gas analysis applications, quartz tubes facilitate the accurate measurement and detection of gases due to their non-reactive surface. This characteristic ensures that the integrity of the sample remains intact, allowing for reliable results in experiments. Additionally, the transparent nature of quartz enables scientists to obtain clear visibility of the contents within the tube, aiding in monitoring and adjustments during experiments.

The chemical resistance offered by quartz tubes is another significant advantage. When subjected to a myriad of corrosive substances, quartz remains stable, minimizing the risk of contamination or compromised experimental conditions. This quality makes quartz tubes indispensable in laboratories where the handling of aggressive reagents is routine. Moreover, when employed in chemical reactions, quartz tubes can withstand the extremes of thermal cycling, making them ideal for combustion processes and other high-temperature reactions.

Furthermore, quartz tubes serve as critical components in various analytical instruments, such as spectrometers and chromatographs. Their integration into these devices often enhances the overall performance and accuracy of measurements. By utilizing quartz instead of glass or plastics, researchers can achieve a higher fidelity in their results, reinforcing the reliability of their scientific inquiries.

In conclusion, the versatility of quartz tubes, combined with their favorable physical and chemical properties, makes them a preferred choice in laboratory settings, contributing significantly to successful experimental outcomes.

Manufacturing Processes for Custom Quartz Instruments

The manufacturing of custom quartz instruments, such as beakers, crucibles, and tubes, involves various intricate processes that ensure high-quality and performance standards. One of the primary techniques employed in the production of these quartz instruments is melting. This process begins with high-purity quartz crystals which are carefully selected to remove impurities that could affect the final product. The quartz is then subjected to extremely high temperatures in a furnace, where it transitions into a molten state. The control of temperature and atmosphere during melting is critical to achieving the desired viscosity and purity of the molten quartz, thus ensuring the quality of the final instruments.

Following the melting process, molding techniques come into play to form the quartz material into specific shapes. Molding can be accomplished through various methods, including hand casting, where the molten quartz is poured into pre-designed molds. Alternatively, more advanced techniques like centrifugal casting can be employed, particularly for creating hollow forms such as tubes. Molds are designed with precision to accommodate the intricate shapes and dimensions required for specialized laboratory instruments. Each mold must be crafted to withstand the high temperatures of the molten quartz, while also allowing for the expansion and contraction of the material during the cooling phase.

Precision machining is another essential process in the manufacturing of custom quartz instruments. Once the quartz pieces have cooled and set, they often require additional refinement to meet exact specifications. This can involve processes such as grinding, polishing, and drilling to create smooth surfaces and accurately dimensioned features. State-of-the-art CNC (computer numerical control) machinery is frequently utilized to enhance accuracy and consistency in the machining process. This level of precision is vital, particularly for instruments that will be used in high-stakes laboratory settings where performance and reliability are paramount. Through these carefully controlled processes, manufacturers can create custom quartz instruments that meet the stringent expectations of users in scientific domains.

Quality Control and Standards in Production

Quality control is an essential aspect of the manufacturing process for laboratory quartz instruments, including beakers, crucibles, and tubes. The integrity of these instruments is paramount, as they are widely used in various experimental setups where precision and reliability are crucial. Maintaining high standards in production not only ensures durability but also guarantees that these instruments can withstand the rigorous demands of laboratory environments.

One of the primary objectives of quality control in quartz instrumentation manufacturing is to establish strict adherence to industry standards. Various organizations, including ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization), provide guidelines that help manufacturers ensure that their products meet specific durability and safety criteria. These standards outline the acceptable quality levels for materials, design, and manufacturing processes, facilitating the production of reliable laboratory quartz instruments.

To maintain these high standards, manufacturers often utilize several testing methods during the production phase. These can include thermal shock testing, which assesses the ability of quartz instruments to withstand sudden temperature changes without cracking or shattering. Additionally, dimensional checks ensure that the instruments’ measurements conform to predefined specifications, which is critical for achieving accurate experimental results. Other assessments may involve chemical resistance testing to verify that the instruments maintain integrity when exposed to various substances commonly used in laboratories.

Furthermore, consistent monitoring throughout the production cycle is vital. Implementing a comprehensive quality management system allows manufacturers to identify and address any weaknesses or defects promptly. By ensuring that all laboratory quartz instruments undergo rigorous quality control procedures, manufacturers contribute to safe and efficient laboratory practices. This is particularly significant as laboratories increasingly rely on high-quality instruments to support cutting-edge research and development initiatives.

Future Trends in Laboratory Quartz Instruments

As the scientific community continues to evolve, the demand for advanced and versatile laboratory tools is on the rise. Custom laboratory quartz instruments, including beakers, crucibles, and tubes, are increasingly becoming integral to a variety of research applications. The future of these instruments is likely to be shaped by emerging trends that focus on enhancing performance, durability, and usability.

One significant trend is the integration of advanced materials that can withstand extreme conditions while maintaining chemical inertness. Researchers are exploring the potential of composite materials that combine the thermal resistance of quartz with the strength of polymers. Such innovations could lead to the development of lightweight, yet resilient laboratory quartz instruments that expand the scope of their applications in fields such as material science and nanotechnology.

Moreover, automation and precision engineering are expected to play a pivotal role in the manufacturing of custom quartz instruments. The adoption of 3D printing technology is gaining traction, allowing for the rapid prototyping of designs tailored to specific experimental needs. This capability not only facilitates the rapid iteration of instrument designs but also allows for personalized features to meet unique research requirements, which is especially beneficial in specialized laboratory settings.

Sustainability is another pressing theme in the future of laboratory quartz instruments. As researchers become more aware of their environmental footprint, the demand for sustainable manufacturing processes and recyclable materials is increasing. Companies are likely to invest in eco-friendly production methods while ensuring that their products do not compromise on quality or performance.

In conclusion, the future of custom laboratory quartz instruments is poised for transformative advancements. By focusing on new materials, innovative manufacturing techniques, and sustainable practices, scientists can expect tools that not only enhance their research capabilities but also contribute positively to the environment, paving the way for groundbreaking discoveries across various scientific disciplines.