Introduction to Quartz Glass

Quartz glass, also known as fused silica, is a unique form of glass made primarily from silicon dioxide (SiO2) in its most pure state. The process of manufacturing quartz glass involves melting high-purity silica sand at high temperatures, typically exceeding 1,700 degrees Celsius. This results in a material that possesses exceptional optical clarity and minimal impurities, setting it apart from standard glass types, which often contain various additives that can alter their physical characteristics and optical properties.

One of the most significant properties of quartz glass is its remarkable transparency to ultraviolet (UV) light. Unlike conventional glass, which tends to absorb UV radiation, quartz glass allows for unimpeded passage of light wavelengths ranging from the UV spectrum to the infrared (IR) spectrum. This broad transmission range is a critical factor in its utilization for optical fibers and lasers, where light propagation efficiency is paramount.

Furthermore, quartz glass exhibits superior thermal stability compared to other glass types. It has a low thermal expansion coefficient, allowing it to withstand drastic temperature changes without distortion or breakage. This property is particularly important in applications that involve high-intensity laser systems, where localized heating can occur. The ability to maintain structural integrity under such conditions is vital for the performance and longevity of optical devices.

Additionally, quartz glass displays excellent chemical resistance, making it suitable for use in a variety of environments where exposure to corrosive substances might occur. Its resilience against chemical degradation ensures that optical components retain their clarity and functionality over extended periods. Consequently, these unique attributes render quartz glass an indispensable material in the realms of fiber optics and laser technology.

The Importance of Optical Fibers

Optical fibers play a crucial role in modern communication systems, underpinning the infrastructure of data transmission across the globe. Constructed from silica glass or plastic, these fibers transmit information via light signals, allowing for rapid communication speeds that surpass traditional methods. Essentially, they consist of a core surrounded by a cladding layer, which reflects light back into the core, facilitating minimal loss of signal over long distances. This mechanism is foundational to their functionality, enabling telecommunications, internet services, and various other digital applications.

One of the foremost advantages of optical fibers compared to traditional copper wires is their ability to handle significantly greater bandwidth. This property allows for the transmission of larger quantities of data at higher speeds, making optical fibers essential for burgeoning high-speed internet demands. As data consumption continues to rise due to streaming services, cloud computing, and online gaming, the need for efficient data transmission methods has never been more apparent. Optical fibers offer a solution that not only meets these demands but also supports future scalability.

Moreover, optical fibers exhibit higher resistance to electromagnetic interference when compared to their copper counterparts. This characteristic results in clearer signals and reduced crosstalk, making them ideal for long-distance communication. Additionally, due to their lightweight and small diameter, optical fibers are easier to install, leading to lower costs in construction and maintenance of network infrastructure.

As society increasingly transitions to digital platforms, the demand for optical fibers continues to escalate. This trend underscores the need for ongoing innovations in fiber materials and technologies, which are integral to advancing the capacity and reliability of communication networks worldwide. With their myriad advantages, optical fibers are positioned to remain at the forefront of communication technology in the years to come.

How Quartz Glass is Used in Optical Fiber Production

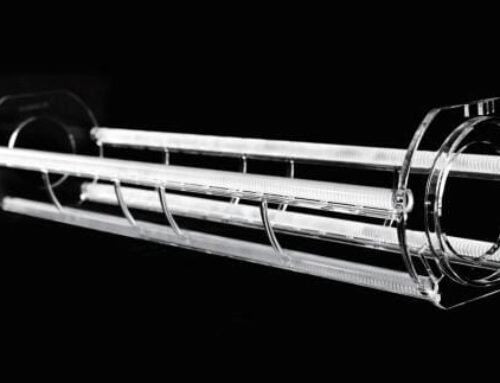

Optical fibers serve as the backbone of modern communication systems, enabling high-speed data transmission across vast distances. The core material utilized in the manufacture of these fibers is quartz glass, prized for its optoelectronic properties and ability to transmit light with minimal loss. The process of drawing optical fibers from quartz glass preforms is intricate and demands precision at each stage to ensure optimal performance.

The manufacturing process begins with the creation of a quartz glass preform. This preform is a cylindrical rod of high-purity silica glass that is designed to possess both the core and the cladding necessary for light guidance. The quality of the quartz glass used for the preform is paramount, as impurities may lead to signal degradation and affect the optical properties. Therefore, high-energy melting techniques are employed to achieve the utmost purity, ensuring that the resulting preform has minimal defects.

Once the quartz glass preform is optimized, it undergoes a process known as fiber drawing. This involves heating the preform in a furnace until it softens and can be drawn into a thin filament. The process requires careful control of temperature and tension, as any inconsistencies can lead to variations in diameter, which directly affect the optical fiber’s signal integrity. The drawn optical fiber, often measuring just a few micrometers in diameter, retains the properties of the original quartz glass, which helps minimize attenuation and increases the efficiency of data transmission.

Furthermore, during the fiber drawing process, additional coatings may be applied to enhance the mechanical strength and protection of the fibers. This ensures that the optical fibers can withstand external stressors while maintaining their excellent optical performance. The synergy between high-quality quartz glass and precise manufacturing techniques is crucial in producing reliable optical fibers that meet the demands of contemporary telecommunication applications.

Laser Production Overview

Lasers, or Light Amplification by Stimulated Emission of Radiation, are devices that emit light through a process of optical amplification. The fundamental principle behind lasers involves the excitation of atoms or molecules, leading to the emission of light of a specific wavelength. This emitted light is coherent, meaning it has a consistent phase relationship, which is a critical feature that distinguishes lasers from other light sources. The coherence and monochromatic nature of laser light result from the stimulated emission process that occurs in a gain medium.

There are several types of lasers, each characterized by the type of gain medium used. Solid-state lasers, such as Ruby and Nd:YAG lasers, utilize solid materials, while gas lasers, like the Helium-Neon laser, rely on gaseous substances. Semiconductor lasers, commonly used in optical devices, are based on quantum mechanics principles, while fiber lasers use optical fibers as the gain medium. The choice of laser type varies according to the intended application, which encompasses a wide array of fields including telecommunications, manufacturing, medical procedures, and scientific research.

Advancements in laser technology have been significantly influenced by the introduction of quartz glass. Quartz glass plays a crucial role in the construction of high-performance laser systems, particularly in fiber lasers where it is utilized for the fiber mediums. Its high temperature resistance and low absorption characteristics allow for effective light transmission and enhanced laser performance, contributing to increased efficiency and reliability. Moreover, quartz glass is pivotal in the fabrication of resonator cavities and lenses, which are essential components for focusing and directing laser beams. The continued integration of quartz glass in laser systems demonstrates its indispensable role in evolving laser technologies.

The Role of Quartz Glass in Laser Manufacturing

Quartz glass, known for its exceptional properties, plays a critical role in the manufacture of lasers. Its unique characteristics make it an ideal material for various laser components, including cavities, windows, and lenses. One of the primary attributes of quartz glass is its superior optical clarity, which allows for minimal absorption and scattering of light. This ensures that the laser can produce a coherent and focused beam, essential for applications ranging from industrial cutting to medical procedures.

Moreover, quartz glass exhibits a high degree of thermal stability, making it suitable for use in environments where lasers produce intense heat. By effectively handling thermal expansion and contraction, quartz glass minimizes the risk of compromising the integrity of laser systems during operation. This resilience to temperature fluctuations is paramount, especially in high-power lasers where operational conditions can be extreme.

The unique chemical composition of quartz glass also imparts enhanced durability, enabling it to withstand the rigors of manufacturing processes and operational use. Unlike traditional glasses, which may have lower resistance to thermal and mechanical stress, quartz glass maintains its structural integrity over extended periods. This reliability not only boosts the performance of laser systems but also reduces maintenance costs and downtime.

In addition, the transparency of quartz glass spans a broad spectrum of wavelengths, making it versatile for different laser types, including solid-state, fiber, and gas lasers. This versatility facilitates advancements in laser technology, allowing for innovative applications across various sectors, such as telecommunications, medical devices, and precision manufacturing.

Overall, the role of quartz glass in laser manufacturing is indispensable, contributing to the efficiency and effectiveness of laser systems primarily through its optical properties, thermal stability, and durability.

Comparative Analysis: Quartz Glass vs. Other Materials

When evaluating materials for optical fiber and laser production, quartz glass, often referred to as silica glass, stands out due to its exceptional optical properties and durability. However, it is essential to compare these attributes with those of alternative materials, including various plastics and other forms of glass.

One of the most significant advantages of quartz glass is its high transparency to ultraviolet (UV) and visible light, which ensures minimal attenuation of signals in optical fibers. This characteristic is particularly vital in telecommunications, where signal loss can drastically impact performance. In contrast, plastics, such as PMMA (poly(methyl methacrylate)), although lighter and more cost-effective, generally exhibit higher levels of light loss, especially at shorter wavelengths. This limitation can hinder their effectiveness in high-speed data transmission.

Regarding thermal stability, quartz glass is favored for applications requiring high operating temperatures. It can withstand extreme thermal conditions without deforming or losing its structural integrity. Plastics, on the other hand, tend to degrade or warp under elevated heat, making them less suitable for environments where temperature fluctuations occur frequently. In the realm of traditional glass, while borosilicate glass provides decent thermal resistance, it does not offer the same level of UV transparency or minimal thermal expansion as quartz glass.

Despite its many benefits, quartz glass is not without drawbacks. The brittleness of this material makes it inherently more susceptible to breakage, posing challenges in handling and installation. Additionally, the production costs associated with quartz glass can be significantly higher compared to plastics, making it a less economical choice for certain applications. However, for high-performance optical fibers and lasers, the superior properties of quartz glass often outweigh these disadvantages.

In conclusion, while quartz glass presents some challenges, its unmatched optical and thermal properties make it a critical material in the fields of optical fiber and laser manufacturing when compared to other materials like plastics and alternative glasses.

Challenges in Quartz Glass Production

The production of high-quality quartz glass is fraught with a variety of challenges that impact both the material’s availability and its suitability for applications, particularly in optical fiber and laser technologies. One significant issue is the sourcing of suitable raw materials. The purity of silica sand, which is the primary component of quartz glass, is critical. Impurities such as iron and other metallic oxides can adversely affect the optical properties of the glass, leading to decreased transmission efficiency and performance. As a result, manufacturers must ensure they source high-purity silica from vetted locations, and this can sometimes lead to scarcity and supply chain complications.

Another challenge lies in the manufacturing process itself. Producing quartz glass requires extreme precision and control of temperatures during the melting and forming stages. Even minor variations during these processes can result in defects, such as bubbles or inconsistencies in refractive index. Furthermore, the complexity of the production methods often necessitates the use of specialized equipment that can be both costly and subject to operational limitations. This precision is essential for applications in optical fibers, where uniformity in glass quality is paramount to maintain signal integrity and reduce losses.

With the rapid evolution of technology, there is an ongoing demand for innovation in quartz glass production. Manufacturers are continually exploring new ways to enhance material performance while reducing production costs and environmental impacts. This includes the development of more efficient manufacturing techniques and the exploration of alternative materials that may replace traditional quartz glass in certain applications. As the demand for high-quality optical components grows, addressing these challenges becomes increasingly important to ensure the continued advancement of the industry.

Future Trends in Optical Fiber and Laser Technologies

The field of optical fiber and laser technologies is poised for transformative changes, driven by rapid advancements in material science, particularly in the production and application of quartz glass. With the increasing demand for high-speed internet and the proliferation of data-driven applications, the evolution of optical fibers is essential. Innovations in quartz glass manufacturing are critical, as they enhance the efficiency and durability of optical fibers. This evolution signifies a shift towards fibers that can operate over longer distances with minimal loss, catering to the needs of telecommunications and data centers.

In addition, the healthcare industry is experiencing a significant shift due to advancements in laser technologies. Medical procedures are becoming less invasive, relying heavily on high-precision lasers for treatments ranging from ophthalmology to oncology. The continuous improvements in quartz glass properties allow for greater control over laser wavelength and intensity, thereby fostering the development of more effective medical devices. This is expected to not only improve patient outcomes but also expand the range of applications for lasers in medicine.

Moreover, research into photonic technologies is gaining traction, with quartz glass playing a critical role in the design of novel optical components. These innovations could lead to the advent of highly integrated communication systems, potentially revolutionizing data transmission capabilities. As industries embrace the Internet of Things (IoT), the demands on fiber optic infrastructure will only increase, solidifying the need for high-quality quartz glass.

Furthermore, sustainability considerations are influencing new production techniques for quartz glass. As industries strive for eco-friendly practices, advancements in manufacturing processes may decrease carbon footprints while maintaining high performance. This multifaceted approach not only enhances the quality of optical fibers and lasers but also supports global sustainability efforts.

Conclusion

In conclusion, quartz glass plays an indispensable role in the production of optical fibers and lasers, which are foundational technologies in communication, medicine, and various industrial applications. The unique properties of quartz glass, such as its excellent thermal stability, low absorption, and high transmission efficiency, enable it to serve as a highly effective medium for light transmission. This makes it a preferred choice for manufacturers engaged in the production of optical fibers. The clarity and consistency of quartz glass are critical in minimizing signal loss and enhancing the overall performance of fiber optics systems.

Furthermore, the significance of quartz glass extends into the realm of laser technology. Its ability to withstand extreme temperatures and its chemical resistance make it an ideal candidate for laser components. Whether used in laser rods, lenses, or other optical devices, quartz glass ensures high operational efficiency and prolonged lifespan, thereby contributing to advancements in sectors such as telecommunications, medicine, and material processing. The continuous evolution of laser technology relies heavily on the advancements achieved in quartz glass manufacturing and design.

As technology progresses, the demand for high-quality optical components is likely to increase, amplifying the need for superior quartz glass. The ongoing research and development efforts aimed at enhancing the properties of quartz glass may yield innovative solutions that can further push the boundaries of what is possible in optical fiber and laser applications. Thus, the future of quartz glass in these fields remains bright and promising, positioning it as a cornerstone in shaping the technological landscape.