Introduction to Quartz Glass

Quartz glass, also known as fused quartz, is a type of glass made primarily from silicon dioxide (SiO2). This unique composition gives quartz glass several distinct properties that make it particularly favorable for optical applications, including its exceptional optical clarity and low thermal expansion coefficient. Unlike standard glass, which may contain various additives and impurities, quartz glass is formed through high-temperature melting of high-purity silica, resulting in a highly homogeneous material with optimized characteristics for precision use.

One of the most notable properties of quartz glass is its high damage threshold. This is crucial in applications involving intense lasers, as it can withstand high-energy impacts without fracturing or deforming. The ability of quartz glass to maintain structural integrity under thermal stress is attributed to its low thermal expansion, which minimizes the risk of thermal shock when subjected to rapid temperature changes. This property is essential in many laser systems where materials are rapidly heated and cooled.

Additionally, quartz glass exhibits excellent transparency across a broad spectrum of wavelengths, from ultraviolet to infrared. This wide transmission range makes it an ideal choice for various optical devices, such as lenses, prisms, and windows. Its minimal absorbance and refractive index stability over a range of wavelengths further enhance its suitability in optical applications, where precision and efficiency are paramount.

These unique characteristics of quartz glass not only make it a preferred material in optics and laser technology but also highlight its vital role in advancing scientific and industrial applications. As we delve deeper into the specific uses of quartz glass in these fields, understanding its foundational properties will prove instrumental in appreciating its significance.

Optical Clarity and Transparency

Quartz glass is recognized for its exceptional optical clarity and transparency, attributes that significantly enhance precision in various optical applications. Unlike traditional glass, quartz possesses a unique ability to minimize light scattering and absorption, leading to a superior transmission of light. This property is critical in applications requiring precise laser optics, as any imperfection or distortion in material can lead to inaccuracies in performance.

The inherent characteristics of quartz glass enable a distinct advantage in environments demanding high performance. For instance, in the field of laser technology, the transmission rates of quartz exceed those of standard glass, making it the material of choice for high-powered lasers used in industrial cutting and precision machining. The minimal absorption of certain wavelengths allows for a clearer path for the laser beam, thus enhancing its intensity and accuracy during operation.

One prominent application of quartz glass is in the manufacture of lenses and windows for microscopes and telescopes. In these instruments, any form of scattering can obstruct critical details, hampering observational accuracy. Case studies reveal that with quartz optics, scientists and researchers have achieved unprecedented resolutions, allowing for detailed studies of cellular structures and astronomical phenomena. Additionally, quartz’s durability against thermal fluctuations secures its positioning as a preferred material in high-temperature environments, thereby ensuring consistent performance under varying conditions.

Overall, the optical clarity and transparency of quartz glass play a crucial role in advancing technologies that rely heavily on precision optics. By reducing light distortion and enhancing transmittance, quartz glass stands as a cornerstone in the development of high-performance optical devices, solidifying its importance in contemporary science and engineering.

Thermal Stability and Performance

Quartz glass is renowned for its exceptional thermal stability, which plays a pivotal role in its performance within the realms of optics and laser technology. This remarkable material can endure high temperatures without deforming or compromising its optical integrity, a quality that is critical in applications where lasers operate under extreme conditions. Unlike traditional glass, quartz glass exhibits minimal thermal expansion, enabling it to maintain its shape and clarity when exposed to intense heat generated by high-intensity light.

The ability of quartz glass to withstand thermal stress makes it an ideal choice for high-precision laser systems. In these applications, lasers produce substantial amounts of energy, which can significantly elevate temperatures in their operational environment. As a consequence, materials used in laser construction must retain their structural and optical properties despite such challenges. Quartz glass meets these demands effectively; it does not undergo the detrimental thermal changes that could lead to aberrations or render the system ineffective.

Additionally, the stability of quartz glass at elevated temperatures ensures consistency in laser performance. Fluctuations in optical clarity can lead to variations in output quality, which is unacceptable in precision applications. By utilizing quartz glass, manufacturers can mitigate these risks, thereby enhancing the reliability of their laser systems. Moreover, the material is capable of withstanding abrupt temperature changes, making it suitable for environments where high-performance lasers need to operate flawlessly under diverse conditions.

The combination of thermal stability and the preservation of optical properties positions quartz glass as a preferred material in the design and development of advanced laser technologies. Its resilience against high temperatures, alongside its outstanding optical functionality, underlines its importance in achieving precision in optics and laser applications.

Durability and Resistance to Damage

Quartz glass is widely recognized for its exceptional durability, making it a preferred choice in both industrial and scientific applications. Its resistance to physical and chemical damage is superior when compared to traditional glass materials. This robustness is primarily attributed to its unique molecular structure, which enables quartz glass to withstand high temperatures and mechanical stress without compromising its integrity.

One of the notable characteristics of quartz glass is its ability to maintain optical clarity and precision even under harsh conditions. Unlike many other materials that can suffer from thermal shock or chemical etching, quartz glass retains its form and function, making it an ideal option for environments where reliability is paramount. For instance, in laser systems, the precision of the beam can be significantly affected by the quality of the optical components. Quartz glass, with its excellent thermal stability, ensures that the laser’s performance remains consistent, even during prolonged use.

When comparing quartz glass with alternative materials such as borosilicate or regular soda-lime glass, the distinctions become evident. While borosilicate glass exhibits good resistance to thermal shock, it falls short in terms of transmission quality and chemical durability in high-demand applications. Soda-lime glass, commonly used in everyday objects, lacks the essential qualities needed for high-precision optics and does not offer the same level of protection against harsh chemical environments.

In essence, the durability of quartz glass sets it apart, providing a level of resistance that enables its use in intense industrial settings and precise scientific research. Its ability to maintain structural and optical integrity positions it as a superior choice for manufacturing delicate optical instruments and laser systems that require reliability and excellence in performance. The advantages offered by quartz glass serve as a benchmark against which other materials are measured, underscoring its critical role in advancing modern optics and laser technologies.

Applications of Quartz Glass in Optics

Quartz glass, known for its exceptional optical clarity and thermal stability, plays a pivotal role in various applications within the field of optics. One prominent use of quartz glass is in the production of lenses. The high transmittance of quartz glass, which typically exceeds 90% in the ultraviolet (UV) spectrum, makes it an ideal material for UV lenses. Such lenses are crucial in numerous applications, ranging from scientific instrumentation to photolithography in semiconductor manufacturing. The material’s resilience to temperature fluctuations ensures that these lenses maintain their performance under varying environmental conditions.

Another vital application of quartz glass is in the creation of prisms. Quartz prisms are widely used in optical instruments, including spectrometers and cameras, due to their ability to efficiently disperse light into its constituent wavelengths. This dispersion is critical for various analytical techniques, allowing for precise measurements of light properties. The inherent low thermal expansion of quartz glass further contributes to the stability and accuracy of optical devices, directly enhancing their performance.

Additionally, quartz glass is extensively utilized in the development of optical fibers. Its low absorption losses at various wavelengths make quartz optical fibers an excellent choice for telecommunications and data transmission. By minimizing signal degradation over long distances, quartz fibers facilitate high-speed data transfer, vital in modern communication infrastructures. Recent advancements in optical technology have also led to the production of specialty fiber optics that leverage quartz glass to improve bandwidth and reduce noise, resulting in sharper signal performance.

Overall, quartz glass significantly enhances the precision and effectiveness of optical components. As technology progresses, the continued integration of quartz glass into optical systems promises to yield even more specialized and efficient applications, setting the stage for innovations in fields such as astronomy, telecommunications, and laser technology.

Role of Quartz Glass in Laser Systems

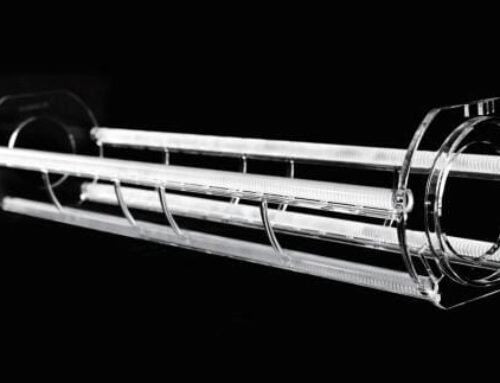

Quartz glass is an integral component in various laser systems, contributing to their performance and precision. Its unique properties, such as high thermal stability, low thermal expansion, and excellent optical clarity, make it a preferred choice for numerous laser applications. In particular, lasers that require high performance, such as solid-state lasers, fiber lasers, and gas lasers, frequently incorporate quartz glass components like mirrors and lenses, as well as protective windows.

One of the key roles of quartz glass in laser systems is in the fabrication of mirror substrates. When utilized as mirrors, quartz glass enables efficient reflection of laser light with minimal distortion, which is crucial for maintaining beam quality. The flatness and optical characteristics of quartz mirrors enhance the collimation of laser beams, resulting in improved focus and precision. Consequently, this leads to enhanced performance in applications such as material processing, medical therapies, and scientific research, where precise laser delivery is essential.

Furthermore, quartz glass is employed as windows in various laser systems, facilitating the transmission of laser beams while offering protection against environmental factors. These windows must provide excellent transmission rates across a wide spectrum of wavelengths, ensuring that the laser operates at its optimal potential. The inherent resistance of quartz glass to mechanical and thermal stresses also makes it ideal for high-powered lasers, which experience significant energy fluctuations during operation.

The compatibility of quartz glass with different coatings allows for further enhancement of laser systems’ efficacy. Anti-reflective and reflective coatings can be applied to the quartz surfaces to optimize the transmission or reflection of specific wavelengths. This tailoring of laser optics is essential for applications requiring precise beam manipulation and high resolution. Overall, quartz glass plays a pivotal role in ensuring the success and reliability of laser systems, significantly impacting their precision and effectiveness across various industrial and scientific domains.

Innovations and Future Trends

Recent developments in quartz glass technology have significantly influenced the fields of optics and lasers, marking a pivotal era of innovation. Researchers are continuously exploring advanced quartz formulations that provide enhanced optical performance. One notable trend is the development of specialty quartz glasses that exhibit a broader range of optical properties, enabling improved transmission in critical wavelengths. These innovations are particularly relevant for applications demanding high precision, such as fiber optic communications and laser systems.

The advancement of coatings applied to quartz glass is another key factor propelling the industry forward. Anti-reflective coatings, for instance, minimize light loss and improve efficiency, leading to enhanced performance in various optical devices. Furthermore, protective coatings offer durability against environmental factors, thereby extending the lifespan of optical components. These developments have substantial implications for industries relying on high-quality optics, including telecommunications, medical devices, and aerospace technology.

In addition to enhancing existing materials, researchers are also investigating novel manufacturing techniques that streamline the production of quartz glass. On-going studies on additive manufacturing methods are particularly encouraging, as they could allow for customized quartz components with intricate geometries that were previously unattainable. This level of customization not only enhances the versatility of quartz glass applications but also paves the way for new designs that optimize performance.

Looking ahead, predictions indicate a future where quartz glass will play an increasingly prominent role in next-generation optical systems. As demand for precision increases in fields ranging from consumer electronics to scientific research, advancements in quartz technology are expected to meet these challenges. The exploration of sustainable practices in quartz glass production will likely further shape the industry, encouraging innovations that balance performance with environmental responsibility. These trends underscore the pivotal impact that quartz glass continues to have on advancing optics and lasers, promising exciting developments in the coming years.

Challenges and Limitations

While quartz glass is widely recognized for its excellent optical properties and resistance to thermal shock, its application in optics and lasers is not without challenges and limitations. One significant challenge is the cost associated with high-purity quartz glass. Producing quartz glass with minimal impurities requires advanced manufacturing processes, which can drive up production costs considerably. This factor can limit the accessibility of quartz glass for some industries, especially when budgets are tight and alternative materials may offer a more cost-effective solution.

Availability is another notable concern. High-quality quartz glass is not as abundantly available as other materials. The extraction and refining processes involved in obtaining pure quartz can be resource-intensive and time-consuming. Factoring in geographical limitations can further complicate the logistics of sourcing this material, leading to delays in production timelines for companies relying on quartz glass for their optical devices.

Moreover, the manufacturing processes associated with quartz glass come with their own set of limitations. Creating components with precise geometries and minimal defects requires highly controlled environments and specialized techniques such as CNC machining or molding. These methods can pose difficulties, especially when tailoring quartz glass for specific applications in optics or lasers, requiring a balance between intricate design and the structural integrity of the material. Additionally, the fragile nature of quartz glass means it is susceptible to breakage during processing, which could lead to increased wastage and additional costs.

Overall, understanding these challenges and limitations is essential for industries engaged in optics and lasers. It not only provides a more nuanced view of quartz glass’s capabilities but also identifies potential areas for improvement that could lead to enhanced usability and affordability in the future.

Conclusion and Key Takeaways

In reviewing the critical role of quartz glass in the domains of optics and lasers, it is evident that this material offers several advantages that enhance precision and functionality. Quartz glass exhibits unique optical properties, such as low thermal expansion and exceptional transparency across a broad spectrum of wavelengths. These characteristics not only contribute to the accuracy of optical systems but also facilitate the reliable transmission of laser light, which is essential for various applications ranging from telecommunications to medical technologies.

Moreover, the inherent durability of quartz glass under extreme conditions makes it an ideal choice for high-performance environments where reliability is paramount. Its resistance to thermal shock and chemical corrosion ensures that precision optics can maintain their integrity and performance over time, a significant concern for industry professionals who work with sensitive and expensive optical components. This robustness further establishes quartz glass as a critical material in the development of advanced optical systems.

As the field of optics and laser technology continues to evolve, industry professionals might explore areas such as optimizing quartz glass manufacturing processes or developing advanced coatings that could further enhance its properties. Investigating alternative compositions or combinations with other materials could lead to innovations that provide even higher levels of precision and efficiency in optical applications.

Ultimately, the selection of materials is crucial in optical design, as it directly influences the performance and accuracy of optical systems. The utilization of quartz glass serves as a prime example of how careful material choices can lead to enhanced capabilities in optics and lasers, making it a subject worthy of continuous research and consideration among professionals in the field.